That frantic morning scramble for a specific part. The last-minute, profit-killing run to the supply house. The mystery of which truck has the component you need right now. If this sounds familiar, you know that managing materials can feel like the most chaotic part of running a trade business. You’re likely relying on a patchwork system of spreadsheets, sticky notes, and memory—a system that springs new leaks every time you add a new truck or technician. It’s time to stop patching and start building a solid foundation. This is where warehouse inventory management software comes in, designed to bring order and predictability to your operations. This guide will walk you through everything you need to know to choose the right system for your business.

Key Takeaways

- Focus on features that solve your core problems: Look for warehouse inventory management software that offers real-time truck stock tracking, mobile access for your team, and seamless integrations with your existing accounting and field service platforms to eliminate your biggest operational headaches.

- Plan your rollout for a smooth transition: A successful switch requires a clear plan for migrating clean data, training your team, and checking in on performance to make sure the new system is working as it should.

- Turn your inventory data into business insights: Go beyond simple part counting and use your warehouse inventory management software’s reporting features to make smarter purchasing decisions, optimize stock levels to improve cash flow, and find hidden cost savings.

What is Warehouse Inventory Management Software?

Think of warehouse inventory management software as the command center for all your parts and materials. It’s a digital tool that helps you track everything you have in stock, from the moment a part arrives from a supplier to the second it’s loaded onto a tech’s truck for a job. Unlike a clunky spreadsheet that’s always out of date, this software gives you a real-time view of your entire inventory.

For trade businesses, this isn’t just about managing a massive warehouse. It’s about controlling the chaos in your stockroom, on your shelves, and across your fleet of vehicles. The goal is to streamline all the activities involved in handling your materials, like receiving new shipments, putting items away, and picking parts for jobs. It replaces guesswork and manual counts with a reliable system that knows exactly where every single screw, filter, and pipe fitting is at all times. This level of organization is what allows you to stop wasting time searching for parts and start focusing on completing jobs and keeping customers happy.

What It Does

At its core, warehouse inventory management software is designed to handle the day-to-day flow of your materials. Most systems come with a set of core features that cover the entire lifecycle of your inventory. This includes logging new items as they’re received from suppliers, assigning them to specific locations like a bin or a service truck, and tracking them as they’re used on jobs. It also helps you manage purchase orders and process returns efficiently. The best software automates these tasks, reducing the manual data entry that leads to errors. It essentially creates a single source of truth for your inventory, so everyone on your team is working with the same accurate information.

How It Helps Your Trade Business

Implementing this kind of software can transform a disorganized stockroom into a smooth, efficient operation. When you have accurate, real-time information about your inventory, you can make smarter purchasing decisions and avoid the last-minute runs to the supply house that kill your profitability. It helps you keep a close eye on your stock levels, preventing you from tying up cash in parts you don’t need or, worse, running out of a critical component mid-job. Ultimately, having the right parts on hand means your techs can work more efficiently, complete more jobs, and keep your customers satisfied. You can even calculate your potential savings to see how much of an impact it could have on your bottom line.

Key Features Your Warehouse Inventory Software Should Have

When you start comparing warehouse inventory management software, the sheer number of options can feel overwhelming. Every platform promises to solve your problems, but they aren’t all built for the unique demands of a trade business. To cut through the noise, focus on the core features that will actually make a difference in your day-to-day operations. The right software should do more than just count parts; it should streamline your entire workflow, from the warehouse to the job site.

Think of these features as your non-negotiables. A good system will give you a clear, real-time view of your stock, automate tedious tasks, and work seamlessly with the other tools you already rely on. It should also provide insights that help you make smarter purchasing decisions and be accessible to your team wherever they are. Let’s break down the essential features you should look for to ensure you’re choosing a tool that will support your business as it grows.

1. Real-Time Inventory Tracking

Knowing exactly what you have and where it is—whether in the warehouse or on a specific truck—is the foundation of good inventory management. Real-time tracking eliminates the guesswork that leads to last-minute supply runs and project delays. When your tech is at a job site, they need to know if the part they need is on their truck. If it’s not, they need to know if it’s in the main warehouse or on another tech’s vehicle. This visibility allows you to manage your inventory efficiently, reduce carrying costs, and ensure your team has the materials they need to complete jobs on the first visit.

2. Automated Order Fulfillment

Manual processes are slow and prone to error. The right warehouse inventory management software can automate key parts of your fulfillment workflow, like generating purchase orders when stock levels dip below a certain threshold. Instead of relying on a manager to remember to reorder popular parts, the system can do it for you. This also applies to job prep. Your software should help you create accurate picking lists for upcoming jobs, ensuring techs are fully equipped before they head out. Automating these tasks frees up your team to focus on more valuable work and reduces the risk of costly mistakes.

3. Seamless Integrations With Your Existing Tools

Your inventory system doesn’t operate in a vacuum. It needs to communicate with the other software you use to run your business, especially your accounting and field service management platforms. A system with strong integration capabilities creates a seamless flow of information, eliminating the need for manual data entry and reducing the chance of errors. When your inventory software syncs with tools like QuickBooks, ServiceTitan, or Jobber, you get a unified view of your operations, from job costing to final invoicing. This ensures everyone is working from the same, up-to-date information.

4. Forecasting and Analytics

Your inventory data is a goldmine of business insights, but only if your software helps you make sense of it. Look for a solution with robust reporting and analytics features. These tools can help you identify your most-used parts, spot slow-moving stock that’s tying up cash, and forecast future demand based on historical data. Good reporting allows you to make data-driven purchasing decisions instead of relying on gut feelings. This helps you optimize stock levels, improve cash flow, and ultimately increase your profitability.

5. Access From Anywhere

Your team isn’t chained to a desk, and your inventory software shouldn’t be either. Cloud-based warehouse inventory management software allows you and your technicians to access critical inventory information from any device, anywhere. Whether they’re at a job site, on the road, or in the warehouse, your team can check stock levels, look up part locations, and update inventory counts in real-time from a phone or tablet. This mobile accessibility is crucial for maintaining accurate data and keeping your field and office teams perfectly in sync.

6. Data Security

Your inventory and purchasing data are valuable business assets, so security is essential. A reliable software solution will offer features to protect your information, including secure cloud hosting, regular backups, and user-based permissions. Permissions are especially important, as they allow you to control who can see and do what within the system. For example, you can give technicians the ability to view and request parts without giving them access to sensitive financial information or purchasing controls. This ensures your data is not only safe from outside threats but also managed properly internally.

The Best Warehouse Inventory Management Software

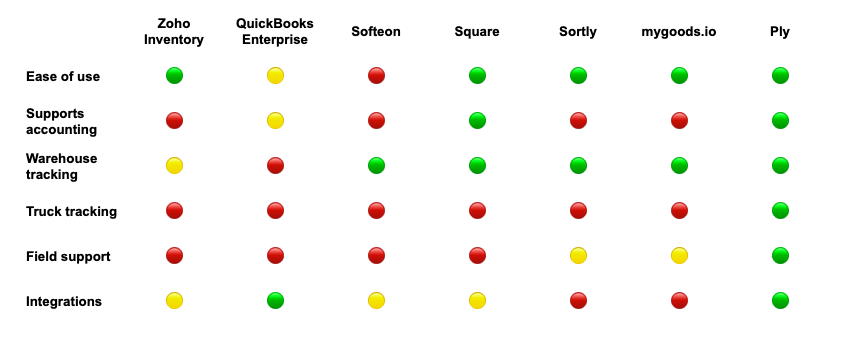

Choosing the right warehouse inventory management software can feel like a huge decision, but it doesn’t have to be overwhelming. The best system for your business depends on your size, budget, and the tools you’re already using. To help you compare, here are some of the top warehouse inventory solutions available—each with its standout strength and a few tradeoffs to consider.

Zoho Inventory

Zoho Inventory is a user-friendly platform that’s great for small businesses looking to move away from manual tracking. It includes basic order management, warehouse support, and integrations with other Zoho apps.

Who it’s for: Small businesses looking for a simple inventory system with light order management features.

What it’s good for: Getting started with digital inventory in a low-risk way—especially if you already use Zoho Books or Zoho CRM.

Shortcomings: Feature set can feel limited for fast-growing contractors, and mobile field usage isn’t its strong suit.

QuickBooks Enterprise

For companies already using QuickBooks for accounting, the Enterprise version includes inventory tools that sync directly with your financials. It’s a good way to keep everything in one system without adding a new platform.

Who it’s for: Companies that already run on QuickBooks and want to consolidate financials and inventory.

What it’s good for: Keeping accounting and inventory tightly linked inside a familiar interface.

Shortcomings: Inventory features are only available in the Enterprise tier, and it’s not designed with warehouse or truck-level tracking in mind.

Softeon

Softeon is a robust, enterprise-grade warehouse management system built for large-scale operations. It’s often used by logistics and distribution firms with complex supply chains.

Who it’s for: Large-scale warehouses with multiple locations and deep operational complexity.

What it’s good for: High-volume warehouses that need deep functionality and custom workflows across multiple distribution centers.

Shortcomings: Overkill for most small-to-midsize businesses—comes with a steep learning curve and enterprise pricing.

Square

Square offers simple inventory tracking as part of its broader point-of-sale system. It’s a good option for retail-facing businesses or contractors who sell direct and want integrated payments.

Who it’s for: Retailers or contractors who sell products and want built-in payment and inventory tracking.

What it’s good for: Combining inventory and payments into a single, beginner-friendly system with low upfront cost.

Shortcomings: Inventory tools are basic, and it’s not built for warehouse management or field coordination.

Sortly

Sortly is a highly visual app designed for teams that need to manage stock on the go. Its barcode scanning and photo-based inventory make it ideal for quick identification.

Who it’s for: Mobile teams or small warehouses that need lightweight, visual inventory tools.

What it’s good for: Field teams or small warehouses that want a mobile-first, easy-to-use system with strong visual cues.

Shortcomings: Lacks deeper functionality like purchasing automation, advanced reporting, or integrations with accounting and service platforms.

mygoods.io

mygoods.io is a lesser-known platform that’s gaining popularity for its simplicity and value. It’s a lightweight solution for teams who’ve found other platforms too bloated or expensive.

Who it’s for: Teams that want a no-fuss, budget-friendly tool to get inventory under control.

What it’s good for: Delivering core inventory management features without the complexity or high cost of enterprise platforms.

Shortcomings: Smaller community and fewer native integrations; may not scale well as your business grows.

Ply

Ply isn’t just another inventory system—it’s a platform built specifically for contractors in the trades, like HVAC, plumbing, and electrical businesses. It combines real-time inventory tracking across warehouses and trucks with powerful purchasing tools and deep integrations into the software you’re already using, like ServiceTitan, Jobber, and QuickBooks.

Where other platforms fall short—limited field visibility, lack of truck-level tracking, poor integration, or complex enterprise features—Ply was designed to fill those gaps. It gives your field techs a simple, mobile-first tool to manage materials on the go, while giving your office team the clarity and control to track costs, reduce waste, and streamline purchasing.

🟡 = Partial fit / Limited capability

🔴 = Not designed for this use case

View Ply’s pricing and plans and explore the Ply platform.

How to Choose the Right Warehouse Inventory Software

Picking the right warehouse inventory management software is a big decision that can shape how your business runs for years to come. It’s about more than just features; it’s about finding a partner that understands the trades and can support your growth. When you’re comparing options, it’s easy to get lost in the details. The key is to step back and look at the bigger picture.

Think about your daily operations. Where are the bottlenecks? Are your techs wasting time searching for parts on their trucks? Is your purchasing process a mess of spreadsheets and sticky notes? The right software solves your most pressing problems without creating new ones. It should feel like a natural extension of your team, making everyone’s job easier, from the office to the field. By breaking the selection process down into a few key steps, you can confidently choose a system that fits your business perfectly and sets you up for success.

1. Define Your Business Needs

Before you even look at a demo, start with a clear picture of what you need. What are the biggest inventory headaches you’re dealing with right now? Maybe it’s inaccurate stock counts, disorganized truck stock, or a purchasing process that’s impossible to track. Make a list of your must-have features versus your nice-to-haves. For example, real-time tracking might be a must-have, while advanced forecasting could be a nice-to-have. Get input from your team—your technicians, warehouse managers, and office staff all have valuable insights. This initial assessment will be your guide, helping you filter out the noise and focus on the solutions that will actually solve your problems.

2. Plan for Future Growth

The warehouse inventory management software you choose today should be able to grow with you tomorrow. Think about where you want your business to be in one, three, or even five years. Will you be adding more technicians, expanding your service area, or opening another warehouse? A scalable solution allows you to add new users, locations, and trucks without a massive price hike or a complicated overhaul. Look for flexible plans and a system built to handle increasing complexity. The goal is to invest in a platform that supports your ambitions, not one you’ll outgrow in a year.

- PRO TIP: Check out Ply’s ROI calculator to see how the right software can pay for itself as you expand.

3. Check for Compatibility

Your inventory software doesn’t operate in a vacuum. It needs to play well with the other tools you rely on every day, like your accounting software and field service management platform. A system that doesn’t integrate with your existing tech stack will only create more manual work and data entry errors. Make a list of the software you currently use (e.g., QuickBooks, ServiceTitan, or Jobber) and look for an inventory solution that offers seamless integrations. When your systems can talk to each other, you get a single source of truth that streamlines everything from purchasing to invoicing, saving you time and preventing costly mistakes.

4. Consider Training and Support

Even the best software is useless if your team doesn’t know how to use it. As you evaluate vendors, pay close attention to the training and support they offer. Do they provide comprehensive onboarding to get you started on the right foot? Is their support team easy to reach when you have a question or run into an issue? Look for a company that acts more like a partner than just a provider. Some companies even offer services like onsite warehouse implementation to ensure your setup is optimized from day one. Strong support is a sign that the company is invested in your success.

5. Map Out Your Implementation Timeline

Switching to a new system takes time and planning. A good software provider will be transparent about the implementation process and help you create a realistic timeline. Ask about data migration—how will you get your existing inventory data, supplier lists, and purchase orders into the new system? A smooth transition is crucial to minimize disruption to your daily operations. Work with the vendor to map out each step, from initial setup and data import to team training and the final go-live date. A well-planned implementation ensures your team feels confident and ready to use the new tool effectively from the start.

Breaking Down the Costs and Value

Let’s talk money. Investing in new software can feel like a big step, but understanding the costs and the value it brings back to your business makes the decision much clearer. The price tag is just one part of the equation; the real win is the long-term return you get from smoother operations, happier techs, and more profitable jobs.

When you start looking at warehouse inventory management software, you’ll find that pricing isn’t one-size-fits-all. The cost depends on the size of your team, the features you need, and the type of pricing model you choose. Thinking through these factors will help you find a solution that fits your budget and sets your business up for success.

Subscription vs. One-Time Purchase

The two main ways you’ll see software priced are through a subscription or as a one-time purchase. A subscription model, also known as Software-as-a-Service (SaaS), is the most common. You pay a monthly or annual fee, which usually includes updates, customer support, and cloud hosting. This approach keeps upfront costs low and predictable.

The alternative is an on-premises solution, where you pay a large, one-time fee for a perpetual license to own the software. You then host it on your own servers. While this means you own it forever, you’re also responsible for maintenance, security, and any future upgrade costs. For most trade businesses, a flexible subscription model is the more practical and affordable choice.

Watch Out for Hidden Costs

The sticker price of software rarely tells the whole story. To create an accurate budget, you need to account for potential hidden costs that can pop up during implementation. Don’t get caught off guard by these common expenses.

Think about the time and resources needed for training your team to use the new system effectively. You might also need to factor in the cost of migrating your existing data, like parts lists and supplier information, into the new software. Other overlooked expenses can include upgrading hardware if your current computers aren’t up to snuff or dedicating IT staff time to the setup process. Asking providers about these costs upfront will save you from surprises down the road.

Calculate Your Long-Term ROI

While it’s important to understand the costs, the real focus should be on the return on investment (ROI). The right software doesn’t just cost money; it makes you money. Think about how much you could save by eliminating last-minute trips to the supply house, reducing inventory shrinkage, or freeing up your techs’ time to complete more jobs each week.

To figure out your potential ROI, start by identifying your biggest inventory pain points. Are you losing track of high-value parts? Is too much cash tied up in slow-moving stock? The right software should directly address these issues. A good system will pay for itself through increased efficiency, better cash flow, and higher job profitability.

How to Plan Your Budget

Ready to build your budget? Start by defining what you absolutely need versus what would be nice to have. Make a list of your must-have features, like real-time truck stock tracking or integration with your accounting software. This will help you focus on solutions that meet your core requirements without paying for bells and whistles you won’t use.

Once you have your list, get quotes from a few different software providers. Be direct and ask them about all potential costs, including setup fees, training packages, and support plans. This will give you a complete picture of the total investment required. Remember, the right software for your business is one that fits both your operational needs and your financial reality.

It’s easy to get excited about all the new features, but it’s just as important to anticipate the challenges you might face.

Common Roadblocks (And How to Get Past Them)

Switching to a new software system can feel like a huge undertaking, and let’s be honest, it sometimes comes with a few bumps in the road. It’s easy to get excited about all the new features, but it’s just as important to anticipate the challenges you might face. The good news is that most of these hurdles are common, and with a little foresight, you can create a plan to get past them smoothly. From getting your inventory counts just right to making sure your new tool plays nicely with your existing software, we’ll walk through the most frequent roadblocks and give you actionable steps to clear them.

Keeping Your Counts Accurate

One of the biggest reasons to get inventory software is to finally get a handle on what you actually have in stock. But if your initial counts are off, you’re starting on the wrong foot. Manual counting is tedious and full of opportunities for human error, which leads to frustrating discrepancies down the line. The solution is to lean on technology. Most modern warehouse management systems use barcode scanning to track items as they come in and go out. This simple step drastically reduces errors and gives you a reliable, real-time view of your inventory. When you’re evaluating software, make sure it has robust inventory tracking capabilities to keep your counts consistently accurate from day one and maintain inventory integrity across your entire operation.

Finding the Right Stock Levels

Walking the line between having too much inventory and not enough is a classic challenge. Too much stock, or overstock, means your cash is tied up in materials sitting on a shelf instead of being put to work. Too little, and you’re dealing with stockouts, which can delay jobs and hurt your reputation. The key is using data to find that sweet spot. Your software should provide clear, real-time information that helps you make smarter purchasing decisions. Look for features like low-stock alerts and usage reports. This data helps you understand how quickly you go through certain parts, allowing you to set optimal stock levels and avoid the costs of both overstock and stockouts, ultimately keeping your customers happy.

Streamlining Order Fulfillment

When a technician needs a part for a job, they need it fast. A disorganized warehouse can turn a simple request into a time-consuming search party, slowing down your entire operation. Effective inventory software helps you manage your warehouse space and streamline the entire fulfillment process. You can assign specific bin locations to every item, making it easy for anyone to find exactly what they need. This creates an efficient workflow, from a tech requesting a part to your warehouse team picking and packing the order. A well-organized system ensures your team can fulfill orders quickly, which makes your whole supply chain more efficient, keeps jobs on schedule, and improves your bottom line.

Managing Multiple Locations

For most trade businesses, inventory isn’t just in one warehouse—it’s also on every truck in your fleet. Managing stock across multiple mobile and stationary locations adds a layer of complexity that can quickly become overwhelming without the right system. You need software that was built to handle this. A good platform will give you a single, unified view of all your inventory, whether it’s in the main warehouse or on a service vehicle. This allows you to track parts, transfer stock between locations, and give your technicians visibility into what’s available nearby. This is crucial for keeping your truck stock organized and ready for any job that comes your way.

Overcoming Integration Headaches

Your inventory software doesn’t operate in a vacuum. It needs to communicate with the other tools you rely on every day, like your accounting platform and field service management software. When these systems don’t connect, you’re stuck with manual data entry, which is not only time-consuming but also a recipe for errors. Before you choose a solution, make sure it offers seamless integrations with your existing tech stack. Whether you use QuickBooks for accounting or ServiceTitan for dispatching, a pre-built connection will ensure data flows automatically between systems. This creates a single source of truth for your business and saves your team from the headache of doing the same work twice.

How to Implement Your New Software

You’ve done the research and picked your new inventory software. That’s a huge step, but the work isn’t over just yet. The way you introduce and set up your new system is just as important as the software itself. A bumpy rollout can create frustration and slow down adoption, while a smooth transition sets your team up for success from day one. The key is to have a clear, step-by-step plan.

Think of it less as flipping a switch and more as a phased project. You’ll need to move your data, train your team, and make sure everything is running as expected. It might sound like a lot, but breaking it down into manageable stages makes the entire process feel much less overwhelming. A good software partner will also provide support during this stage, whether it’s through remote help or an onsite warehouse implementation to get you started on the right foot. By planning ahead, you can avoid common pitfalls and start seeing the benefits of your new system almost immediately.

- PRO TIP: Ply offers onsite warehouse implementation helps your team use Ply to its full potential

1. Plan Your Data Migration

Before you can use your new software, you need to feed it the right information. This process is called data migration, and it’s essentially moving all your inventory data—like part numbers, descriptions, supplier details, costs, and current quantities—from your old system (or spreadsheets) into the new one. This is your chance for a fresh start. Take the time to clean up your existing data before you move it. Get rid of duplicate entries, fix typos, and make sure all your information is accurate and consistent. A clean dataset is the foundation for reliable inventory tracking, so this initial effort will pay off for years to come.

2. Get Your Team On Board

New software is only effective if your team actually uses it. Getting your crew on board starts with clear communication and proper training. Explain why you’re making the switch and how it will make their jobs easier—less time searching for parts, fewer stockouts on a job site, and clearer communication between the warehouse and the field. Involve your key technicians and warehouse managers in the training process early on. When they feel comfortable with the system, they can become champions for it and help their colleagues. Seeing how other trade businesses have succeeded with new software can also help motivate your team and show them what’s possible.

3. Monitor Your Performance

Once your new system is live, the job isn’t quite done. The first few weeks and months are critical for making sure everything is working correctly and delivering the results you expected. Schedule regular check-ins at the 30, 60, and 90-day marks to review how things are going. Are your inventory counts accurate? Is the ordering process smoother? Are your techs finding what they need? This is the time to identify any small issues before they become big problems, make adjustments to your workflows, and provide extra training where it’s needed. Monitoring performance ensures you’re getting the full value out of your investment.

4. Know Which Metrics to Track

To truly understand if your new software is working, you need to track the right numbers. Don’t get lost in a sea of data; focus on a few key performance indicators (KPIs) that directly impact your bottom line. Start with inventory accuracy (is what the system says you have what you actually have?), inventory turnover rate (how quickly are you selling through stock?), and order fulfillment time (how long does it take to get parts ready for a job?). Tracking these metrics will give you a clear picture of your operational health and help you make smarter, data-driven decisions.

Get the Most Out of Your Software

Once your new warehouse inventory management software is up and running, the real work begins. Simply having the tool isn’t enough—you need to actively use its features to see a real return on your investment. Think of it as moving from a basic flip phone to a smartphone; you get so much more value when you explore the apps and settings. By digging into what your software can do, you can streamline your operations, make smarter business decisions, and find new ways to improve your bottom line. This is your chance to move beyond just tracking parts and start using data to build a more resilient and profitable business.

Find Ways to Automate More

Your team’s time is valuable, so don’t waste it on tasks the software can handle for you. Look for every opportunity to automate manual processes. You can set up automatic reorder points for frequently used parts, so purchase orders are generated before you run out. Connect your inventory system to your accounting software to eliminate double data entry and keep your financials accurate. The goal is to let the technology handle the repetitive work, which frees up your technicians and office staff to focus on what they do best: serving customers and completing jobs. These automated workflows are the key to a more efficient and less error-prone operation.

Use Reports to Make Smarter Decisions

Your inventory software is constantly collecting valuable data. Don’t let it just sit there—use it. Dive into the reporting and analytics features to understand your business on a deeper level. Run reports to see which parts have the highest turnover, which jobs are the most profitable, and where you might be losing money on materials. Having accurate, real-time information about your inventory helps you make smart decisions about everything from pricing your services to negotiating with suppliers. These insights turn your warehouse from a simple storage space into a strategic asset for your company.

Fine-Tune Your Inventory Strategy

A great inventory strategy strikes a balance between having enough stock to meet demand and not tying up too much cash in materials sitting on a shelf. Use your software to set and adjust min/max levels for every item in your warehouse and on your trucks. Pay attention to forecasting tools that can predict future needs based on past job data and seasonality. This allows you to create a more proactive purchasing plan. You can also easily identify slow-moving or obsolete items, giving you the chance to offload them instead of letting them take up space and capital. This level of control is crucial for managing inventory across a central warehouse and multiple service vehicles.

Spot Opportunities to Save Money

Better inventory management directly translates to cost savings, and your software will help you find them. By preventing stockouts, you can avoid last-minute, expensive trips to the supply house. Accurate tracking helps reduce shrinkage from misplaced or lost materials. You can also use purchasing data to consolidate orders and negotiate better pricing with your top suppliers. Over time, these small savings add up to a significant impact on your profitability.

Related Articles

- Truck Stock Management Basics: Auditing, Barcoding, and Organization

- How Tariffs and Supply Chain Costs Are Driving Up Prices for Skilled Trades—and How Inventory Management Can Help

- Smart Inventory Management Tips for Field Service Teams

Frequently Asked Questions

Is this kind of software only for large businesses with big warehouses?

Not at all. This software is just as valuable for a small business with a stockroom and a few service trucks as it is for a large company with a massive warehouse. The core problem it solves is the same regardless of size: knowing what materials you have and where they are at all times. For trade businesses, managing inventory across multiple trucks is often a bigger headache than managing a central stockroom, and that’s exactly what this software is designed to simplify.

We’re using spreadsheets to track inventory now. Why should we switch?

Spreadsheets are a good starting point, but they have major limitations. They require constant manual updates, are prone to human error, and can’t give you a real-time picture of your stock. A dedicated inventory system automates much of that work, reducing mistakes and giving everyone on your team access to the same accurate information. It turns your inventory data from a static list into a dynamic tool that helps you make smarter purchasing decisions and streamline your entire operation.

My team isn’t very tech-savvy. Is this software hard to learn?

That’s a common and completely valid concern. The best modern inventory software is designed with usability in mind, especially the mobile apps that technicians use in the field. Look for a system with a clean, intuitive interface. More importantly, choose a software provider that offers solid training and ongoing support. A good partner will work with you to make sure your entire team feels confident using the new tool from day one.

How does this software help my technicians when they’re out on a job?

This is where the software really shines. Instead of guessing what’s on their truck, a tech can simply look at an app on their phone to see their exact stock. If they don’t have a part they need, they can instantly see if it’s in the main warehouse or on another nearby truck. This visibility dramatically cuts down on time-wasting trips to the supply house, allowing your techs to complete jobs faster and move on to the next one.

How long does it typically take to get a new inventory system up and running?

The timeline can vary depending on how much inventory data you have and how clean it is. A simple setup might take a few weeks, while a more complex implementation could take a couple of months. The process usually involves migrating your parts data, setting up your warehouse and truck locations in the system, and training your team. A good software provider will map out a clear implementation plan with you to ensure a smooth and predictable transition.