Do you know how much disorganized inventory is truly costing your business? It’s more than just the price of misplaced parts. It’s the payroll hours your team wastes searching for materials, the fuel burned on last-minute supply house runs, and the cash tied up in overstocked items collecting dust on a shelf. These hidden costs eat away at your profitability every single day. Investing in warehouse and inventory management software is about plugging these financial leaks. By giving you complete visibility and control over your materials, the right system helps you make smarter purchasing decisions, reduce waste, and ensure every dollar you spend on inventory is working for you.

Key Takeaways

- Turn Inventory from a Cost to an Asset: Ditch the spreadsheets and manual counts to get a real-time, accurate view of your materials. This allows you to prevent costly stockouts while avoiding tying up cash in overstocked parts, making your inventory work for you.

- Focus on Features That Solve Field Problems: The best software isn’t the one with the most features—it’s the one that makes your techs’ jobs easier. Prioritize mobile access, barcode scanning, and seamless integrations with your field service and accounting tools to create a smooth workflow from the office to the job site.

- Set Your New System Up for Success: A smooth transition requires more than just buying software. Prepare for success by cleaning up your inventory data before you move it, getting your team involved early, and confirming the platform can adapt to your unique workflows.

What Is Warehouse and Inventory Management Software?

Ever had a job grind to a halt because a technician didn’t have the right part on their truck? Or spent hours manually counting boxes in your warehouse, only for the numbers to be off again a week later? That’s the exact chaos that warehouse and inventory management software is designed to eliminate. Think of it as a central command center for all your physical assets—from the parts in your main warehouse to the tools stocked on every service vehicle. It gives you a real-time, bird’s-eye view of what you have, where it is, and how it’s moving.

This type of software goes far beyond a simple spreadsheet. It automates the tedious work of tracking stock levels, managing purchase orders, and even following materials as they move from a supplier to your warehouse and out to a job site. Good software helps you streamline your warehouse operations by setting up automated reorder points, so you never run out of critical parts again. It replaces guesswork with data, ensuring your team has what it needs to get the job done right the first time.

Ultimately, the goal is to give you complete visibility and control over your inventory. Instead of wasting money on parts you already have or losing jobs due to stockouts, the software provides the clear data you need to make smarter purchasing decisions. It helps you meet customer demand without tying up cash in overstocked shelves. By connecting your purchasing, warehouse, and field operations, you can finally get a handle on your materials and focus on growing your business.

Why Invest in Warehouse and Inventory Management Software?

If you’re still relying on spreadsheets or pen and paper to track your materials, you know the frustration. It’s a constant battle of chasing down parts, dealing with last-minute runs to the supply house, and wondering what’s actually on each truck. This isn’t just an administrative headache; it’s a direct hit to your bottom line. Every hour a tech spends searching for a part is an hour they aren’t on a billable job. Every project delayed by a stockout is a risk to your reputation.

Investing in warehouse and inventory management software is about taking control of your operations. It’s a shift from a reactive, often chaotic approach to a proactive, streamlined system. This software gives you a clear, real-time view of your entire inventory—from the main warehouse to every service vehicle. It automates the tedious tasks that eat up your team’s time and provides the data you need to make smarter purchasing decisions. Think of it as the central nervous system for your materials, connecting your purchasing, your warehouse, and your field techs so everyone is working from the same playbook. This isn’t just another expense; it’s a foundational tool for scaling your business, improving profitability, and delivering the reliable service your customers expect.

Stop Wasting Time on Manual Tracking

Manual inventory tracking is a time sink, plain and simple. Counting parts by hand, updating spreadsheets, and trying to decipher messy handwriting are slow processes that are full of opportunities for human error. A single misplaced digit can lead to ordering the wrong part or thinking you have an item in stock when you don’t. This is time your team could be spending on more valuable activities, like completing jobs or providing great customer service.

Good software helps you automate these tasks, giving you back precious hours in the day. By replacing manual counts with barcode scanning and automatic updates, you reduce errors and get instant, accurate data. This means your team can find what they need quickly and you can trust the numbers in your system, all without the tedious manual effort.

Prevent Costly Stockouts and Overstocking

Walking the line between too much and too little inventory is a major challenge. Stockouts are a top pain point for a reason: they bring projects to a screeching halt, forcing techs to make unplanned trips to suppliers and delaying job completion. This not only frustrates your team but also damages your relationship with customers. On the flip side, overstocking ties up your cash in materials that are just sitting on a shelf, collecting dust and risking damage or obsolescence.

Inventory management software gives you the data to find the sweet spot. By tracking usage patterns, you can set automatic reorder points for high-demand items, ensuring you always have what you need without carrying excessive stock. This data-driven approach to purchasing helps you calculate your true cost savings and turns your inventory from a liability into a well-managed asset.

Simplify Your Multi-Location Operations

As your business grows, so does the complexity of your inventory. Managing materials across a central warehouse, multiple storage units, and a fleet of service vehicles can feel like an impossible juggling act. Without a centralized system, you have no easy way of knowing if the part a tech needs is on another truck just a few miles away. This lack of visibility leads to redundant purchases and wasted time as techs scramble to find what they need.

The right software provides a single source of truth for your entire inventory. With multi-location management features, you can track materials wherever they are—in the warehouse, on a truck, or at a job site. This complete visibility allows you to transfer stock efficiently between locations, reduce unnecessary purchases, and ensure your team is always equipped for the job at hand.

Fulfill Orders Faster and More Accurately

In the trades, speed and accuracy are everything. Customers want their problems fixed correctly and on the first visit. A key part of making that happen is ensuring your technicians have the right parts and tools on their trucks when they arrive. When a tech has to leave a job site to pick up a forgotten part, it doubles the travel time, delays the project, and leaves the customer waiting.

Integrating your inventory system with your field service software creates a seamless workflow from the office to the field. When a job is dispatched, you can ensure all necessary materials are allocated and loaded onto the correct vehicle. This preparation drastically improves first-time-fix rates and streamlines the entire process from picking to installation. Better order accuracy means your team can work more efficiently, complete more jobs, and keep customers happy.

- PRO TIP: An online ROI calculator will help you determine the value of software

Must-Have Features in Warehouse and Inventory Management Software

When you start looking at different software options, the sheer number of features can feel overwhelming. It’s easy to get lost in flashy dashboards and long lists of capabilities. But to find a tool that will actually make a difference for your business, you need to focus on the core functions that solve real-world problems. The right software isn’t just a digital list of your parts; it’s a central hub that streamlines how you order, track, and use materials across your entire operation.

A solid platform will give you a clear, real-time view of what you own and where it is, whether it’s on a warehouse shelf or in the back of a service truck. It should also automate tedious tasks like reordering and connect seamlessly with the other software you rely on every day. Think of it as the foundation for a more efficient, profitable business. Let’s walk through the essential features you should look for.

✅ Real-Time Inventory Tracking

Knowing what you have in stock is fundamental, but knowing it in real time is a game-changer. Real-time tracking means you can see your inventory levels update instantly as parts are used on a job, moved between locations, or received from a supplier. This eliminates the guesswork that leads to costly mistakes. Your technicians in the field can confidently check if a part is available without having to call the office or drive back to the warehouse. This immediate visibility helps you manage your inventory accurately, prevent project delays, and keep your customers happy by ensuring your team always has the right materials to finish the job.

✅ Automated Reordering and Stock Management

How much time do you or your team spend manually checking stock levels and creating purchase orders? Automated reordering takes that entire task off your plate. You can set minimum and maximum stock levels for your most-used items. When inventory drops to a certain point, the software can automatically generate a purchase order or notify you that it’s time to reorder. This proactive approach helps you avoid stockouts of critical parts that can bring a job to a halt. It also prevents overstocking, so you aren’t tying up cash in materials that just sit on the shelf. It’s a simple way to maintain optimal inventory levels without the constant manual effort.

✅ Mobile Access and Barcode Scanning

Your team isn’t sitting behind a desk all day, so your inventory software shouldn’t be stuck there either. Mobile access is essential for trade businesses. It allows your technicians to view stock levels, request parts, and update inventory directly from their phones or tablets in the field. When paired with barcode scanning, it becomes even more powerful. A tech can simply scan a part’s barcode to check it out of their truck stock, instantly updating your central inventory count. This drastically reduces human error, gets rid of messy paperwork, and gives you a precise, up-to-the-minute record of material usage on every single job.

✅ Seamless Integrations with Your Existing Tools

The most effective inventory software doesn’t work in a silo. It should connect smoothly with the other systems you already use to run your business. Look for a platform that offers seamless integrations with your field service management software—like ServiceTitan, Housecall Pro, or Jobber—and your accounting platform, such as QuickBooks or Sage Intacct. When your systems talk to each other, you eliminate double data entry and create a single source of truth. Purchase orders can flow directly into your accounting software, and material costs can be automatically assigned to the correct job, simplifying job costing and improving overall operational efficiency.

✅ Clear Reporting and Analytics

Data is only useful if you can understand it. Great inventory software does more than just hold your data; it helps you make sense of it through clear reporting and analytics. You should be able to easily run reports on inventory turnover, usage trends, and carrying costs. These insights help you make smarter purchasing decisions, identify slow-moving or dead stock, and understand the true profitability of your jobs. With the right data, you can see which materials are your most profitable and calculate the ROI of your inventory, turning your warehouse from a cost center into a strategic asset.

✅ Support for Multiple Locations and Channels

As your business grows, managing inventory across multiple locations—like a central warehouse and a fleet of service trucks—becomes increasingly complex. Your software needs to be able to handle this. Look for a system that provides a unified view of all your inventory, no matter where it’s physically located. This allows you to track stock levels in each truck, transfer parts between locations, and get a complete picture of your assets at a glance. Effective truck stock management ensures your technicians are always prepared, reducing unnecessary trips to a supplier and increasing the number of jobs they can complete in a day.

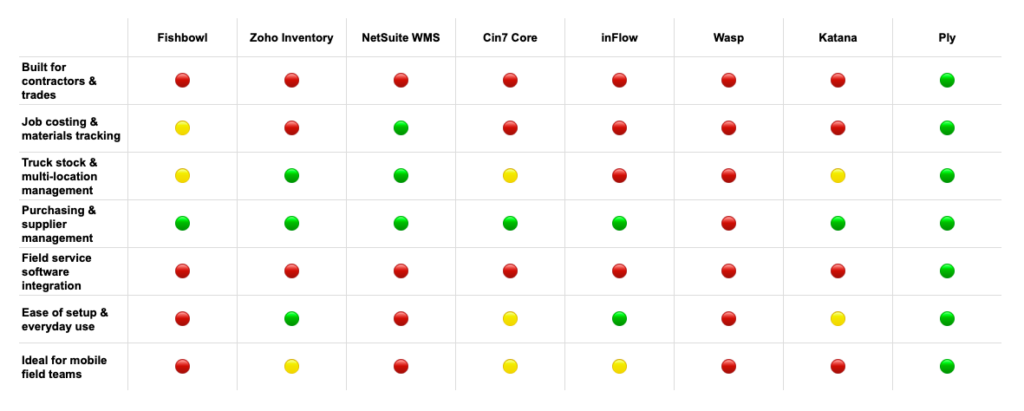

A Head-to-Head: The Best Warehouse and Inventory Management Software

Choosing warehouse and inventory management software isn’t about finding the flashiest interface or longest feature list—it’s about choosing a system that fits how your business really operates. A plumbing company managing truck stock has completely different needs than an e-commerce brand shipping out of multiple fulfillment centers. Most platforms are built for retail, distribution, or manufacturing—not for the day-to-day realities of contracting.

Here’s a breakdown of the top options on the market, what they do well, where they fall short, and why Ply stands apart for construction and trade businesses.

Ply – Built for Contractors

For contractors, the warehouse is just one piece of the puzzle—your real inventory is spread across every truck in your fleet. Ply is built specifically for this reality. It helps you maintain ideal stock levels across warehouses, trucks, and job sites, giving you real-time visibility into what’s available, where it is, and what’s running low. With native integrations for ServiceTitan, Housecall Pro, Jobber, and QuickBooks, Ply connects inventory directly to your field service and accounting workflows. That means fewer supply-house runs, fewer missed parts, and better job costing—all without the complexity of enterprise software.

Fishbowl Inventory – Strong Automation, Steep Setup

Fishbowl is a mature, feature-rich solution that automates manual tracking and integrates tightly with QuickBooks. It’s ideal for light manufacturing and distribution companies—but often feels heavy and overengineered for contractors. Setup and customization can take weeks, and many users report that Fishbowl features meant for warehouses or production lines add unnecessary layers for service-based teams. It’s a capable system, but for small or mid-size contractors, it’s often more horsepower (and cost) than you need.

Zoho Inventory – Flexible, But Generic

Zoho Inventory offers impressive cloud-based scalability and multi-warehouse management, especially if you’re already using other Zoho tools. But that flexibility comes with a catch: it’s a general-purpose system. It’s not designed for job-based inventory, technician workflows, or truck stock tracking. Contractors can make it work with custom fields and manual tweaks, but it’s a workaround—not a natural fit.

NetSuite WMS – Comprehensive, but Overkill for Most

NetSuite’s warehouse management module is powerful, with deep analytics, KPI dashboards, and ERP-level control. It’s perfect for large enterprises that want to centralize every part of their operation under one umbrella. But that sophistication comes at a steep price—in both money and complexity. For contractors and small construction firms, NetSuite is often far more system than necessary. It’s a data powerhouse, but not a practical field tool.

Cin7 Core – Great for Retail, Misaligned for Service

Cin7 Core excels in retail and e-commerce environments, where syncing online and in-store stock is critical. It’s optimized for sales orders, shipping, and fulfillment—not for tracking material usage on jobs. Its integrations revolve around shopping carts and POS systems, not field service software. For contractors, that means you’ll end up paying for tools you’ll never use while still needing spreadsheets for the things you actually do.

inFlow Inventory – Simple, but Limited

inFlow is a strong starter platform for small businesses getting organized. It’s easy to learn, affordable, and handles the basics like stock tracking, order management, and barcode scanning. The tradeoff? It’s light on advanced functionality. There’s no built-in field service integration, no real-time truck stock visibility, and limited purchasing automation. It’s a nice on-ramp for general inventory management, but you’ll quickly outgrow it in a field-based business.

Wasp Barcode Solutions – Complete Hardware System, Outdated Software

Wasp stands out by offering both hardware and software in one package, which is handy for companies building an inventory system from scratch. But the software itself feels dated and clunky compared to newer, cloud-based platforms. It’s better suited for fixed warehouse environments than mobile field operations. If your technicians need real-time access in the field, Wasp’s old-school setup can slow you down.

Katana Manufacturing ERP – Excellent for Makers, Inefficient for Installers

Katana is a top-tier solution for manufacturers who need to manage raw materials, production runs, and work-in-progress items. But that’s exactly why it’s a poor fit for contractors. It’s production-centric, requiring you to allocate materials to “production orders” rather than jobs or trucks. For service-based teams, it’s simply too process-heavy and not aligned with how you operate in the field.

Why Ply Wins for Trade and Construction Teams

Most warehouse and inventory systems were built for selling, shipping, or manufacturing—not for managing parts that move from warehouses to trucks to job sites. Ply bridges that gap. It combines real-time visibility, mobile access, and deep field service integrations in a simple, contractor-friendly platform.

While other systems either overwhelm or underdeliver, Ply strikes the balance: powerful enough for scale, intuitive enough for daily use. For construction and trade businesses that want to run leaner, smarter, and more profitably, Ply is the clear choice.

Understanding the Costs: What to Expect

When you’re ready to invest in warehouse and inventory management software, the price tag is obviously a huge consideration. The cost can range from free to thousands of dollars a month, depending on the complexity of your business and the features you need. Most software providers use a tiered pricing model, so you can find a plan that fits your current needs and scales with you as you grow. Let’s break down the common pricing structures you’ll encounter so you can budget accordingly.

The Limits of Free Software

Free software can seem like a great deal, and for a brand-new business or a one-person shop, it might be a decent starting point. These tools are typically very basic versions of paid platforms, offering just enough functionality to track a small number of products. However, “free” almost always comes with significant limitations. You’ll likely run into caps on the number of users, orders you can process per month, or warehouses you can manage. As your business grows, you’ll quickly hit these limits and be forced to upgrade, so it’s best to view free plans as a temporary solution rather than a long-term strategy.

A Look at Subscription-Based Models

This is the most common pricing structure for modern, cloud-based inventory software. You’ll pay a monthly or annual fee, typically based on factors like the number of users, features included, and the number of locations you manage. For small to mid-sized businesses, you can expect to pay anywhere from $100 to $500 per user each month. While this is a real investment, the right software pays for itself by eliminating costly errors, reducing carrying costs, and saving your team countless hours. You can even calculate the return on your investment to see how quickly the savings add up.

When to Consider Enterprise and Custom Pricing

If you’re running a larger operation with multiple warehouses, a big team, and complex workflows, a standard subscription plan might not cut it. This is where enterprise-level and custom pricing come in. These plans are tailored specifically to your business needs and often include advanced features like supply chain management, dedicated support, and direct integrations with enterprise resource planning (ERP) software. Pricing is usually quote-based, but you can expect it to be significantly higher than off-the-shelf plans, often running well over $800 per month. This option is best for established businesses that need a powerful, customized system to manage their scale.

Preparing for Common Implementation Hurdles

Switching to a new software system can feel like a massive project, but it doesn’t have to be a headache. The key is knowing what to expect. When you anticipate the common bumps in the road, you can plan for a much smoother transition for you and your team. Let’s walk through the four main hurdles you might encounter: integrating with your current tools, getting your team on board, moving your data cleanly, and handling your unique workflows. By preparing for these ahead of time, you can start reaping the benefits of your new system much faster.

A successful rollout is all about preparation. By thinking through your integrations, team training, data migration, and specific business needs ahead of time, you set yourself up for a win. The right software partner will also guide you through this process, offering support and resources to make each step manageable. Think of it not as a challenge, but as the first step toward a more efficient and profitable operation. This proactive approach turns a potentially stressful project into a strategic move that strengthens your business from the ground up, ensuring the technology works for you, not the other way around.

Integrating with Your Current Systems

Your business already runs on a set of tools you trust, whether it’s QuickBooks for accounting or a field service platform like ServiceTitan to manage jobs. Your new inventory software shouldn’t operate on an island; it needs to connect seamlessly with your existing systems. A lack of integration can lead to manual data entry and disconnected workflows, defeating the purpose of upgrading in the first place. Look for a solution with a robust library of pre-built integrations that are designed for your industry. This ensures that when a tech uses a part on a job, the information flows directly from your inventory system to your job costing and accounting software without anyone having to lift a finger.

Getting Your Team Onboard

The best software in the world won’t make a difference if your team doesn’t use it. Change can be met with resistance, especially if your crew is used to a certain way of doing things. The trick is to get them involved early and show them what’s in it for them. Frame the new system as a tool that makes their jobs easier—no more guessing what’s on the truck, fewer trips to the supply house, and less tedious paperwork. Start by identifying a few champions on your team who can help test the software and provide feedback. Provide clear, hands-on training sessions that are relevant to their specific roles. When your technicians and warehouse managers see the software as a solution to their daily frustrations, they’ll be your biggest advocates for a successful rollout.

Migrating Your Data Cleanly

Moving your existing inventory data—from parts lists to supplier information—into a new system is a critical step. Many businesses run into trouble here because their current data is messy, inconsistent, or incomplete. Taking the time to clean up your data before you migrate it is essential. This means standardizing part names, removing duplicate entries, and ensuring all your information is accurate and up-to-date. Think of it as spring cleaning for your inventory. A clean data migration prevents a “garbage in, garbage out” scenario, ensuring your new system starts with a reliable foundation. Some software providers offer onsite implementation and data migration support, which can be a huge help in getting this done right the first time without overwhelming your team.

Handling Customization Needs

No two trade businesses operate exactly the same way. You have unique workflows for purchasing, managing truck stock, and handling returns. A one-size-fits-all software solution might force you to change processes that already work well for you. The challenge is finding a system that is flexible enough to adapt to your specific needs without requiring a team of developers to customize it. Before you start shopping, document your most important workflows. How do you create purchase orders? How do you track materials from the warehouse to the job site? Share this with potential software providers and ask them to show you exactly how their system can handle your processes. The goal is to find a platform that supports your way of working, not one that forces you into a box.

- PRO TIP: Ply Provides On-Site Implementation Services

Who Benefits Most from This Software?

While nearly any business that handles physical products can find value in this software, some industries feel the impact more than others. If your daily operations revolve around tracking, moving, and using physical goods, then a dedicated management system isn’t just a nice-to-have—it’s essential for growth and efficiency. From construction sites to retail warehouses, the right software transforms chaotic processes into streamlined, predictable workflows. It helps you gain control over your assets, reduce waste, and ultimately serve your customers better. Let’s look at a few key sectors where this technology makes the biggest difference.

Construction and the Trades

For contractors in the trades, inventory isn’t sitting neatly on a single set of shelves. It’s spread across a central warehouse, multiple job sites, and a fleet of service trucks. This complexity makes it incredibly difficult to know what you have and where it is. The right software brings order to this chaos, allowing you to manage your stock in less time. You can maintain preferred inventory levels for any location, ensuring your technicians always have the parts they need to finish a job on the first visit. This prevents costly delays, eliminates last-minute runs to the supply house, and keeps your projects on schedule and on budget.

Manufacturing and Distribution

In manufacturing and distribution, the warehouse is the heart of the operation. Success depends on the efficient flow of goods, from receiving raw materials to shipping finished products. Warehouse management software helps automate and streamline these complex operations. It provides real-time visibility into every stage of the production and fulfillment process, reducing errors and improving accuracy. By tracking raw materials, work-in-progress, and finished goods with precision, you can optimize production schedules, manage supplier relationships more effectively, and ensure that every item that leaves your facility is accounted for and correctly routed.

Retail and E-commerce

For retailers, nothing hurts sales more than an “out of stock” message. Whether you sell online, in a physical store, or both, keeping up with customer demand is a constant challenge. Inventory management software gives you access to real-time data, so you always know what’s available to sell. This is crucial for omnichannel retail, where you need to sync stock levels across multiple channels instantly. By automating tasks and reducing human error, you can prevent overselling, fulfill orders faster, and provide a seamless shopping experience that keeps customers coming back.

Healthcare and Food Service

In industries like healthcare and food service, inventory management is about more than just profit—it’s about safety and compliance. Products often have expiration dates, require specific storage conditions, and must be traceable by lot number. A simple stockout could have serious consequences. This software must include robust quality control features to address issues before products reach the customer. It enables precise tracking to ensure a first-in, first-out (FIFO) system, reduces waste from expired goods, and provides the documentation needed to meet strict regulatory standards, protecting both your business and the people you serve.

How to Measure Your Software’s ROI

Investing in new software feels like a big step, so you want to be sure it’s actually paying off. Measuring the return on investment (ROI) isn’t just about seeing a number on a spreadsheet; it’s about confirming that the tool is solving the problems you bought it for. Is it saving your team time? Are you wasting less money on materials you don’t need? Are your jobs running more smoothly?

The right software should make a tangible difference in your day-to-day operations. By tracking the right metrics, you can move beyond a “gut feeling” and see exactly how your investment is impacting your bottom line and your team’s efficiency. This data gives you the confidence that you made the right choice and helps you identify new ways to streamline your business. Think of it as a report card for your software—one that shows you where you’re winning and where you can make even greater improvements. The goal is to have clear proof that your new system is helping you work smarter, not just harder.

Key Performance Indicators (KPIs) to Track

Think of Key Performance Indicators (KPIs) as the vital signs for your inventory. They are specific, measurable values that show you how well your material management process is working. Instead of guessing if things are improving, inventory management KPIs give you hard data. For a contracting business, this could mean tracking things like how often you have the right part on the truck (order fill rate), the total value of inventory you’re holding, or how long materials sit on the shelf before being used. By consistently monitoring these numbers, you can spot trends, catch problems before they get out of hand, and make informed decisions that save you time and money.

Measuring Inventory Turnover and Accuracy

Two of the most important metrics to watch are inventory turnover and accuracy. Inventory turnover tells you how quickly you’re using your materials over a certain period. A high turnover rate is generally good—it means you aren’t tying up cash in stock that just sits there. On the other hand, inventory accuracy measures how well your records match what’s actually on your shelves and in your trucks. A high inventory accuracy rate is critical. For contractors, it’s the difference between a tech finishing a job in one visit or having to make a costly, time-wasting trip back to the shop or supply house for a forgotten part.

Gauging Order Processing and Fulfillment Speed

How long does it take to get the right materials into a technician’s hands? This is what order processing and fulfillment speed measures. This KPI tracks the entire process, from the moment a part is requested to when it’s ready for the job. A key part of this is the picking cycle time, which is the time it takes to find and pull an item from your warehouse. Tracking the time it takes to complete this process helps you spot bottlenecks. Slow fulfillment can delay jobs, frustrate your team, and hurt your customer service. By speeding this up, you get your techs to the job site faster, allowing them to complete more work each day.

Calculating Your True Cost Savings

Your true cost savings go far beyond just getting a better price on parts. Think about all the hidden expenses that come from disorganized inventory. This includes the labor cost of techs searching for materials in the warehouse or on their truck, the fuel and vehicle wear from extra trips to the supply house, and the money tied up in overstocked items that may never get used. You should also consider the costs associated with processing returns for incorrect parts. A great way to see the potential impact is to use an ROI calculator that helps you quantify these savings. When you add it all up, the financial benefit of an efficient system becomes incredibly clear.

How to Choose the Right Software for Your Business

With so many options on the market, picking the right software can feel overwhelming. The key is to remember that the “best” platform isn’t a one-size-fits-all solution—it’s the one that solves your specific problems and fits seamlessly into how you already work. Instead of getting distracted by flashy features you might never use, focus on what your business truly needs to run more smoothly and profitably.

A little prep work upfront can save you a lot of headaches later. By taking a methodical approach, you can confidently choose a system that not only addresses your current challenges but also grows with you. Think of it as creating a blueprint for your decision. Start by identifying your biggest operational hurdles, map out how a new tool would connect with your existing software, plan for your future goals, and get a clear picture of the total investment. This process will help you cut through the noise and find the perfect fit.

Step 1: Define Your Biggest Pain Points First

Before you even look at a demo, grab a pen and paper and list what’s not working. What are the daily frustrations that cost you time and money? For many businesses, the top inventory management pain points are stockouts that lead to lost jobs or carrying excess inventory that ties up cash.

Is your main issue tracking parts on service trucks? Are you spending hours manually creating purchase orders? Do you struggle to know what you have in the warehouse versus what’s in the field? Be specific. This list becomes your scorecard for evaluating different software options. It helps you prioritize must-have features over nice-to-haves, ensuring you choose a solution that solves real problems from day one.

Step 2: Map Out Your Integration Needs

Your inventory software won’t operate in a silo. It needs to communicate with the other tools you rely on to run your business, like your accounting platform and field service management software. A lack of integration can create data-entry nightmares and operational bottlenecks. Before you commit to a new system, you need to understand the challenges in implementing software that doesn’t connect properly.

Make a list of your essential software—think QuickBooks, ServiceTitan, Jobber, or Housecall Pro. Then, as you evaluate potential inventory solutions, confirm they offer seamless, pre-built integrations with your tech stack. This ensures that information flows automatically between systems, keeping your financial records and job details perfectly in sync without extra manual work.

Step 3: Consider Your Future Growth

The software you choose today should still work for you three to five years from now. Think about your business goals. Are you planning to add more technicians and service vehicles? Will you open a second warehouse or expand into a new service area? Your inventory management system needs to be able to scale with you.

Look for a platform that can easily handle more users, manage multiple locations, and process a higher volume of parts and materials without slowing down. A system that supports scalability prevents you from having to go through this entire selection process again in a few years. Choosing a flexible solution ensures your software remains an asset, not a limitation, as your business expands.

Step 4: Compare the Total Cost of Ownership

The monthly subscription fee is just one piece of the puzzle. To make a smart financial decision, you need to understand the total cost of ownership. This includes any one-time setup or implementation fees, costs for data migration, training for your team, and charges for ongoing customer support. Some platforms also charge extra for premium features or integrations.

Ask for a detailed breakdown of all potential costs before signing a contract. A clear understanding of the software pricing models will help you avoid unexpected bills. You can also use an ROI calculator to estimate the potential savings in time and materials, giving you a complete picture of how the investment will pay off for your business.

Related Articles

- A Trade Guide to Inventory & Warehouse Management Software

- Best Warehouse Inventory Management Software of 2025

Frequently Asked Questions

My business is pretty small. Is this kind of software overkill for me?

Not at all. In fact, small businesses often feel the pain of inefficiency the most. Think of it this way: every hour you or your team spends searching for a part or making an emergency run to the supply house is an hour you can’t bill for. This software isn’t about adding complexity; it’s about creating a solid foundation so you can grow without the chaos. It helps you get organized from the start, ensuring you can take on more jobs without everything falling apart.

How is this really better than the spreadsheet I’m using now?

A spreadsheet is a static list that’s outdated the moment you save it. It can’t tell you in real time what a technician just used on a job, and it relies completely on manual updates, which is where mistakes happen. Proper inventory software is a living system. It updates automatically, gives your whole team access to the same accurate information from their phones, and can even reorder parts for you. It replaces guesswork with certainty.

What’s the single most important feature for a contractor to look for?

For any business in the trades, the ability to manage multiple locations is non-negotiable. Your inventory isn’t just in one warehouse; it’s on every truck in your fleet. You need a system that can track materials across all these mobile locations. This gives you a complete view of all your assets, so you can see if a part is on another tech’s truck nearby instead of buying it again. This feature directly impacts your first-time fix rate and your bottom line.

How do I get my technicians to actually use a new system?

The key is to show them how it makes their job easier, not harder. Frame it as a solution to their biggest frustrations. This software means no more guessing what’s on the truck, fewer last-minute trips to the supply house, and less time spent on paperwork. Get them involved in the selection process and start with clear, hands-on training that focuses on the tasks they perform every day. When they see it as a tool that helps them get home earlier, they’ll be on board.

Will this software connect with my other tools, like my accounting or dispatching software?

It absolutely should. The most effective inventory software doesn’t work in isolation; it acts as the central hub for all your materials. Look for a platform that offers direct, pre-built integrations with the field service and accounting software you already use. This connection is what eliminates double data entry and ensures that material costs from a job automatically flow into your accounting system, giving you a true understanding of your job profitability without any extra work.