There comes a point in every growing business when the old way of doing things just doesn’t cut it anymore. For contractors, that tipping point is often with inventory. It shows up as “ghost” inventory —items that exist on paper but not on the shelf, jobs getting delayed by a single missing part, and the constant, nagging feeling that you don’t have a true handle on your material costs. These aren’t just minor headaches; they are signs that you’ve outgrown manual tracking. Adopting simple inventory management software is the logical next step to regain control and build a more efficient, profitable operation.

Key Takeaways

- Ditch the spreadsheet for real-time control: Manual tracking costs you time and money through stockouts and over-ordering. A dedicated system gives you an accurate, live view of your inventory, so you can make smarter purchasing decisions and keep your trucks properly stocked.

- Connect your field and office with key features: Focus on non-negotiable tools like mobile barcode scanning and seamless integrations with your accounting and field service software. This ensures everyone works from the same data, which cuts down on errors and manual entry.

- Find the right fit by defining your needs first: Before looking at demos, identify your biggest inventory headaches. Choose a system that solves those specific problems, works well with your other software, and allows you to test it with your team before committing.

What is Simple Inventory Software (And Why Do You Need It)?

If you’ve ever found yourself digging through a van for a part you thought you had or making a last-minute run to the supply house, you already know the pains of inventory management. Simple inventory software is the answer to that chaos. It’s a digital tool designed to help you efficiently track, organize, and manage your stock without needing a degree in logistics. Think of it as a central hub for everything you own—from the fittings in your warehouse to the filters on each tech’s truck.

Unlike a messy spreadsheet or a clipboard that can get lost, this software gives you a real-time picture of what you have and where it is. The goal isn’t to add another complicated system to your plate; it’s the opposite. Simple inventory software is built to streamline your process, helping you keep just the right amount of stock on hand. This means you can stop guessing, reduce waste, and make sure your team has what they need to get the job done right the first time. For growing businesses in the trades, getting a handle on materials is non-negotiable. It’s the foundation for accurate job costing, faster service calls, and a healthier bottom line.

The Hidden Costs of Manual Tracking

That trusty spreadsheet or pen-and-paper system might feel free, but it comes with hidden costs. Every time a tech has to call the office to check on a part, that’s lost time. Every time you run out of a critical item mid-job, you risk a delayed project and an unhappy customer. These small inefficiencies add up quickly, impacting your cash flow and profitability. Manual tracking often leads to either having too much cash tied up in overstocked inventory that gathers dust or losing money on emergency supply runs and missed job opportunities because you didn’t have what you needed.

How Inventory Software Solves These Problems

Simple inventory software tackles these problems head-on by replacing guesswork with data. Instead of manual counts, you get automated processes and real-time updates every time a part is used or received. This gives you clear, immediate visibility into your inventory levels, both in the warehouse and on every truck. Your team can instantly see what’s available, reducing frantic calls and unnecessary trips. With accurate data, you can generate precise reports, understand your usage patterns, and make smarter purchasing decisions. It’s about giving you the control to ensure your team is always prepared, your jobs run smoothly, and your business operates more efficiently.

Key Features to Look For in Simple Inventory Software

When you start comparing inventory software, the lists of features can feel endless. Instead of getting lost in the details, focus on the core functions that will actually make a difference in your day-to-day operations. The right software should feel like a natural extension of your business, simplifying tasks, not adding new ones. Think about your biggest inventory headaches—whether it’s running out of parts, spending hours on manual counts, or messy purchase orders—and look for the tools designed to solve those specific problems.

1. Real-Time Tracking and Automated Ordering

The most fundamental feature of any good inventory system is real-time tracking. This means that when a technician uses a part on a job, your stock levels update instantly across all devices. It’s the only way to get an accurate picture of what you have in the warehouse and on each truck, at any given moment. This visibility helps you avoid last-minute supply runs and job delays. Paired with this is automated ordering. You can set minimum stock levels for essential parts, and when your inventory dips below that threshold, the software can automatically generate a purchase order. This simple automation ensures you never run out of your most-used items and cuts down on administrative work.

2. Barcode Scanning and Mobile Access

For any business with technicians in the field, mobile access is non-negotiable. Your team needs to be able to check stock, find parts, and update inventory directly from their phone or tablet. This is where barcode scanning becomes a lifesaver. Instead of manually typing in part numbers—which is slow and prone to errors—your techs can simply scan a barcode to check an item in or out. This makes tracking everything from truck stock to warehouse shelves fast and incredibly accurate. It closes the loop between the field and the office, ensuring everyone works with the same up-to-date information —a core part of a modern inventory management system.

3. Integrations and Reporting Tools

Your inventory software doesn’t operate in a vacuum. It needs to communicate with the other tools you rely on, especially your accounting and field service management software. Look for a platform that offers seamless integrations with systems like QuickBooks, ServiceTitan, or Jobber. This connection eliminates double data entry and ensures your financial records always match your inventory usage. Strong reporting tools are just as important. Good software will give you clear insights into your inventory, helping you track job costs, identify your most profitable items, and spot slow-moving stock that’s tying up cash. This data is what helps you make smarter purchasing decisions and improve your bottom line.

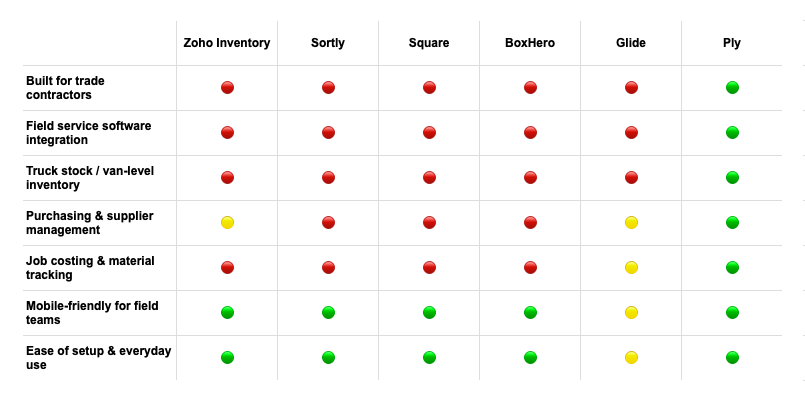

The Best Simple Inventory Software for Small Businesses

Finding the right inventory software feels a lot like finding the right tool for a job—the best one is the one that fits your specific needs. There isn’t a single “best” option for everyone. A plumbing business with five trucks on the road has very different inventory challenges than a small retail shop or a solo maker selling online. The key is to understand what problem you’re trying to solve. Are you losing track of parts in the warehouse? Is truck stock a constant headache? Or do you just need a better way to count what you have than a crumpled piece of paper? The wrong system can create more work than it saves, while the right one can feel like you’ve just hired a new, hyper-efficient team member.

To help you find the right fit, I’ve broken down some of the best simple inventory software tools based on what they do best. We’ll look at everything from comprehensive systems built for contractors to free tools perfect for getting started. Think about your daily operations, your budget, and where you feel the most pain in your current process as you go through this list. This will help you zero in on the software that will actually make your life easier, not just add another login to your password manager. Each tool has its strengths, so matching those strengths to your business’s weaknesses is the goal here.

Ply: For a Complete Contractor Solution

If you’re in the trades, you know that inventory isn’t just about what’s on a warehouse shelf—it’s about what’s in your trucks, what’s been ordered for a specific job, and what your techs need to get their work done. Ply is built from the ground up for this reality. It’s more than just a counting tool; it’s a complete system for managing your materials, from purchasing and receiving to tracking truck stock. Because it’s designed specifically for contractors, it helps you manage parts, equipment, and tools in a way that generic software can’t. Plus, its integrations with platforms like ServiceTitan, Jobber, and QuickBooks mean it fits right into the software you already use to run your business, creating a seamless workflow for your entire team.

Zoho Inventory: For a Free Starting Point

Zoho Inventory’s free plan is a great entry point if you’re a solo operator or just starting to organize your stock. You can track items, manage orders, and sync across channels without paying upfront. But that affordability comes with trade-offs: limited integrations, no job costing, and no way to manage inventory tied to specific work orders or trucks. For contractors, Zoho works as a temporary fix—but you’ll quickly outgrow it once your business needs connected workflows between field and office.

Sortly: For Visual-Based Tracking

Sortly’s strength is simplicity. Its photo-based interface makes it easy for anyone to identify items quickly and keep basic counts up to date. It’s perfect for tool rooms or teams that just need a visual catalog of what’s on hand. But beyond that, Sortly stops short—it doesn’t handle purchasing, job costing, or any deep integration with field service systems. It’s a helpful visual log, not a full inventory engine, so trades that rely on constant part turnover will hit its limits fast.

Square: For Retail and POS Needs

Square’s inventory features shine for businesses that sell products over the counter or online. If you already use Square for payments, its built-in inventory tracking adds nice visibility into what’s selling and what’s low. But for contractors, it’s missing the essentials—no truck stock, no purchase order tracking, and no way to connect parts usage to specific jobs. It’s ideal for a storefront, not for managing the moving pieces of a service fleet.

Other Options to Consider

If you’re simply looking to escape the chaos of spreadsheets, BoxHero is a lightweight and affordable choice that handles item tracking well—but it offers little beyond that. It’s best for teams with static inventory and minimal workflow complexity.

For maximum customization, Glide lets you build your own no-code inventory tracker tied to Google Sheets or another data source. The flexibility is impressive, but the burden’s on you to build and maintain it. For busy contractors, that DIY approach often means more work, not less.

How Much Does Inventory Software Cost?

Let’s talk about the bottom line. When you’re running a business, every dollar counts, and the cost of new software is a huge consideration. The good news is that simple inventory management software isn’t a one-size-fits-all expense. Prices can range from completely free to thousands of dollars per month, depending on the complexity of your operations, the number of users you have, and the specific features you need.

Most software providers use a subscription model, typically billed monthly or annually. This structure makes powerful tools more accessible because you don’t have to pay a massive upfront fee. Instead, you pay a predictable recurring cost that scales with your business. As you grow—adding more trucks to your fleet, more techs to your team, or more items to your warehouse—you can move up to a plan that supports your new needs. The key is to find a tool that not only fits your budget today but also provides a clear path for growth without breaking the bank tomorrow.

Free vs. Paid Plans: What’s the Difference?

Free plans are a great way to dip your toes in the water without any financial commitment. They’re perfect for solo operators or very small shops just starting to organize their inventory. For example, some tools offer a free option that lets you track a limited number of items or process a small handful of orders each month. Others might restrict you to a single location, which can be a dealbreaker if you need to manage stock across multiple service trucks.

While “free” is always tempting, these plans are designed as a starting point. You’ll often find that as your business grows, you’ll quickly hit the limits on item counts, users, or features, forcing you to upgrade to a paid plan to keep things running smoothly.

Breaking Down Subscription Costs

Once you move into paid plans, you’ll typically see tiered pricing. Subscription costs often start around $30 per month for basic plans and can go up from there based on what you need. The price is usually influenced by a few key factors: the number of users who need access, the number of items you’re tracking, and the number of locations (like warehouses or trucks) you’re managing.

It’s easy to get sticker shock, but it’s important to think about the cost in terms of return on investment. How much time are you losing on manual counts? How much money is wasted on last-minute supply runs or over-ordering parts? A good inventory system should pay for itself by cutting down on waste and improving efficiency.

- PRO TIP: Use an ROI calculator to see how the numbers stack up for your specific business

What to Expect from Different Tiers

As you move up the pricing tiers, you unlock more powerful features that are designed to streamline your entire operation. Basic paid plans usually include core inventory tracking, but higher tiers are where you’ll find the game-changers. This includes things like barcode scanning for quick check-ins and check-outs, advanced reporting that gives you a clear picture of your inventory value, and automated purchase ordering.

Most importantly, premium plans offer crucial integrations with the other software you already use, like your accounting platform or field service management tool. This connectivity is what turns your inventory software from a simple tracking tool into the central hub of your operations, ensuring data flows seamlessly from the field to the office.

Learn how BC, Canada-based Fast Track Appliance & Scale took its inventory management up to a new level

What Are Real Users Saying?

Marketing materials can tell you a lot, but the real story comes from the people using these tools day in and day out. Digging into reviews and testimonials gives you an unfiltered look at what works, what doesn’t, and what you can realistically expect. When you’re looking at different software options, hearing from other business owners in the trades is one of the best ways to gauge if a tool will actually solve your problems or just create new ones. Let’s break down the common themes you’ll find.

The Good: Common Praise and Big Wins

When a business finds the right inventory software, the relief is palpable. Users consistently praise systems that are simple to set up and easy to use. The biggest wins come from streamlining the entire inventory and ordering process, turning a chaotic, time-consuming task into something that runs smoothly in the background. As one business owner put it, the right tool can “efficiently [help] handle inventory and customers, automating various business processes.” This isn’t just about saving a few minutes; it’s about creating reliable workflows that reduce errors, free up your team’s time, and give you a clear picture of your stock so you can focus on the actual job at hand.

The Bad: Frequent Complaints and Limitations

On the flip side, many of the complaints you’ll see are rooted in the very problems businesses are trying to solve. The number one pain point is often the consequences of poor management, like stockouts, lost sales, and carrying excess inventory. While software is meant to fix this, a common frustration is that some tools don’t integrate well with other essential systems. Getting your inventory software to communicate with your accounting or field service management platform can be a complex headache. If the systems don’t talk to each other, you’re stuck manually transferring data, which defeats the whole purpose of getting software in the first place.

The Crucial: Is Customer Support Any Good?

So, what often separates a great experience from a frustrating one? Customer support. When you’re implementing a new system that manages a critical part of your business, you need to know that help is available when you need it. Users rave about companies with “phenomenal support” where the team constantly listens to feedback. This is about more than just a helpline; it’s about partnership. The best software providers offer the support and training resources you need to get set up correctly and make the most of your investment. Before you commit, make sure you’re choosing a team that will be there to back you up.

- PRO TIP: Ply offers onsite warehouse implementation

Signs It’s Time for an Inventory System

Switching from a spreadsheet or a clipboard system to dedicated inventory software can feel like a huge leap. You might be thinking, “What I have works well enough.” But “well enough” can quietly cost your business time, money, and even customer trust. The tipping point often isn’t a single event but a series of frustrating problems that start to feel normal. Things like last-minute runs to the supply house, techs calling in because they don’t have the right part on their truck, or discovering you have five of an item you thought you were out of—right after you ordered ten more.

These aren’t just minor headaches; they’re symptoms of a system that can’t keep up with your growth. The hidden costs of poor inventory management add up quickly, from wasted fuel on emergency supply runs to the price of rush shipping. More importantly, it impacts your ability to complete jobs on time, which can damage your reputation. If you find yourself constantly reacting to inventory emergencies instead of proactively managing your materials, it’s a clear signal that your manual methods are holding you back. Recognizing these signs is the first step toward finding a real solution that streamlines your operations and protects your bottom line. Let’s break down the most common red flags.

1. You’re Always Running Out of (or Have Too Much) Stock

Does this sound familiar? You show up to a job only to realize a critical part is missing from the truck. Or, you open a warehouse cabinet and find it overflowing with materials you haven’t used in a year. This constant cycle of stockouts and overstock is one of the biggest inventory management pain points for trade businesses. Stockouts lead to delayed jobs and unhappy customers, while excess inventory ties up cash that could be used elsewhere in your business. An inventory system gives you a clear, real-time view of what you have and where it is, so you can order what you need, right when you need it.

2. Manual Counts Are Eating Up Your Time

How many hours do your techs—or you—spend counting parts in the warehouse or on the truck? That’s valuable time that could be spent on billable work. Relying on manual counts is not only slow but also prone to human error. It’s one of the most common small business inventory mistakes because it leaves you scrambling for supplies when you should be focused on the job at hand. Inventory software automates this process with tools like barcode scanning, turning a tedious, hours-long task into a quick scan. This frees up your team to focus on what they do best: serving your customers.

3. Your Inventory Numbers Never Seem to Add Up

You check your spreadsheet, and it says you have three of a specific filter in stock. But when your tech goes to grab one, the shelf is empty. This “ghost inventory” is a classic sign that your manual tracking system has failed. Without accurate, real-time visibility into your stock levels, you risk reordering items you already have or, worse, disappointing customers with unexpected delays. These discrepancies aren’t just frustrating; they make it impossible to accurately cost jobs and manage your purchasing budget. A reliable inventory system ensures the numbers in your software match the reality on your shelves, giving you the confidence to run your business effectively.

How many hours do your techs—or you—spend counting parts in the warehouse or on the truck? That’s valuable time that could be spent on billable work.

Common Myths About Inventory Software, Busted

If you’ve been holding off on inventory software, chances are it’s because one of these common myths has you convinced it’s not for you. I get it—the thought of changing how you run your business can feel like a huge undertaking. But many of the assumptions that kept contractors away from this technology years ago just don’t hold up anymore. Modern tools are built differently; they’re more accessible, affordable, and intuitive than ever before, designed specifically for the realities of running a trade business.

Let’s clear the air and bust a few of the most persistent myths about inventory management software. You might be surprised to find that the very thing you’ve been avoiding is exactly what your business needs to grow. By moving past these misconceptions, you can gain better control over your materials, reduce waste, and ultimately, run a more profitable operation.

Myth #1: “It’s too complicated for my business.”

The idea of implementing a new system can feel overwhelming, especially when your team is already stretched thin. Many contractors picture clunky, confusing software that requires hours of training just to perform a simple task. But today’s inventory solutions are designed with the end-user in mind—meaning you and your techs. They’re built to be user-friendly and reduce your daily workload, not add to it.

With features like mobile apps for the field and simple dashboards, the goal is to make managing materials easier. A good system should feel intuitive from the start, helping you streamline processes like purchasing and truck stocking without a steep learning curve. It’s about spending less time fighting with technology and more time serving your customers.

Myth #2: “Spreadsheets are good enough.”

Spreadsheets feel familiar and free, which makes them the default for many growing businesses. But “good enough” often comes with hidden costs. Manual data entry is a recipe for human error, leading to incorrect stock counts that can bring a job to a screeching halt. When a tech arrives on-site only to realize the part they need isn’t actually on their truck, it costs you time, fuel, and customer trust.

An inadequate inventory system leaves you scrambling for supplies and guessing what you have on hand. Unlike a static spreadsheet, dedicated software provides a real-time, accurate view of your inventory across every truck and warehouse. This shift from reactive to proactive management is one of the biggest mistakes small businesses can avoid when it comes to their materials.

Myth #3: “It’s too expensive.”

When you hear “software,” you might immediately think of a hefty price tag that only large enterprises can afford. While that may have been true in the past, the market has changed. Modern inventory management tools are built to be flexible and scalable, making them accessible for businesses of all sizes. Many platforms offer different pricing tiers, so you only pay for what you actually need.

Instead of viewing it as a cost, think of it as an investment. The right system pays for itself by reducing material waste, preventing over-ordering, and saving countless hours of labor. You can even use an ROI calculator to see how much you could save by eliminating guesswork and gaining control over your purchasing. The value it provides in efficiency and cost savings often far outweighs the monthly subscription.

Getting Started: Common Implementation Hurdles

Switching to a new inventory system is a big step, and let’s be honest, it can feel a little overwhelming. You’re not just adopting new software; you’re changing a core process that affects everyone from the office to the field. Like any major project, it comes with a few potential bumps in the road. But knowing what to expect is half the battle. The good news is that thousands of businesses have made this transition successfully, and the most common challenges are well-understood. The initial setup phase is where most of the heavy lifting happens. Getting it right means you’ll reap the rewards—like fewer stockouts and more accurate job costing—much faster. By preparing for these hurdles ahead of time, you can ensure a much smoother rollout for you and your team, minimizing downtime and frustration. Here are the three biggest challenges you might face and, more importantly, how to get ahead of them.

Challenge #1: Getting Your Data Into the System

Your first big task is moving all your existing inventory data into the new software. If you’ve been using spreadsheets or even pen and paper, this can feel like a massive undertaking. The key is to ensure all your part numbers, supplier details, and current stock levels are transferred accurately. Any mistakes here can cause headaches down the line. Before you even start the migration, take some time to clean up your current data. Get rid of duplicates, fix typos, and make sure everything is consistent. A clean slate makes the transfer process much easier and sets your new system up for success from day one.

Challenge #2: Getting Your Team On Board

A new tool is only effective if your team actually uses it. It’s natural for people to be a bit resistant to change, especially if they’re comfortable with the old way of doing things. The best way to get everyone on board is to show them what’s in it for them. Will this new software mean fewer frantic trips to the supply house? Less time spent on manual counts? When your techs and office staff understand how the system makes their jobs easier, they’re far more likely to embrace it. Proper training is also crucial, so make sure everyone feels confident using the new tool. Seeing how other contractors have succeeded can also help motivate your team.

Challenge #3: Connecting It to Your Other Tools

Your business relies on a few key pieces of software to run smoothly, from your field service management platform to your accounting software. Your inventory system shouldn’t operate in a silo; it needs to communicate with your other tools. This is where integrations come in. Connecting your inventory software to systems like QuickBooks or ServiceTitan ensures that data flows seamlessly across your entire operation. For example, when a tech uses a part on a job, the inventory count is updated automatically, and the part is added to the customer’s invoice without anyone having to enter it twice. Setting up these integrations is vital for maintaining accurate data and an efficient workflow.

How to Choose the Right Inventory Software for Your Business

Picking the right inventory software can feel like a huge decision, but it doesn’t have to be overwhelming. The secret isn’t finding the tool with the longest feature list; it’s about finding the one that fits how your business actually operates. Think of it like buying a new tool for your truck—you wouldn’t buy a complex gadget you’ll never use. You want something that does the job reliably and makes your life easier.

Before you even start looking at demos, take a step back and think about your current process. What are the biggest headaches? Where are you losing time or money? Are techs constantly calling the office for part numbers? Are you losing track of materials between the warehouse and the job site? Answering these questions first will give you a clear checklist to measure every potential software against. This approach ensures you choose a system that solves your real-world problems instead of just adding another monthly subscription to your expenses.

Define What You Actually Need

Start by making two lists: “must-haves” and “nice-to-haves.” Your must-haves are the non-negotiables. This might include real-time truck stock tracking, barcode scanning from a mobile app, or the ability to create purchase orders. Your nice-to-haves could be things like advanced reporting or cycle count reminders. This simple exercise helps you cut through the marketing noise and focus on the features that will actually impact your bottom line.

Also, consider how you’ll get your existing data into the new system. A clear plan for data migration is essential for a smooth transition. Knowing exactly what you need from day one will help you find a partner, not just a piece of software.

Check if It Plays Nicely with Your Other Software

Your inventory software shouldn’t live on an island. For it to be truly effective, it needs to communicate seamlessly with the other tools you rely on every day. If your team lives in a field service platform like ServiceTitan or Jobber, and your bookkeeper uses QuickBooks, your inventory system must connect to them. Without solid integrations, you’re just creating more manual work for your team, leading to data entry errors and wasted time.

Look for a platform that offers robust, pre-built integrations with your core business systems. This ensures that when a tech uses a part on a job, the information flows directly from their service ticket to your inventory count and finally to your accounting software for accurate job costing. This creates a single source of truth for your materials.

Create a Plan for Testing and Rollout

Once you’ve narrowed down your options, don’t just sign a contract and flip the switch for your entire company. A successful launch starts with a solid plan. Ask for a free trial or an extended demo to let your team get their hands on the software. Set up a small pilot program—maybe with one or two of your most tech-savvy technicians—to track inventory on their trucks for a couple of weeks.

This trial period is the perfect time to test how well the new software connects with your existing systems. Ensuring a seamless data flow between platforms early on will prevent major headaches down the road. Getting feedback from your team during this phase is crucial for buy-in and a smooth, company-wide rollout.

Related Articles

- Best Warehouse Inventory Software for Small Businesses

- 6 Best Accounting Software for Inventory Management 2025

- 7 Best Warehouse Inventory Management Software (2025)

Frequently Asked Questions

My team isn’t very tech-savvy. How hard is it to get them to actually use this?

This is one of the most common concerns I hear, and it’s completely valid. The key is choosing software that’s designed for simplicity. Modern systems, especially those built for the trades, prioritize user-friendly mobile apps with features like barcode scanning. This means your techs can update inventory with a quick scan rather than typing in long part numbers. The best way to get your team on board is to show them how it makes their job easier—no more guessing what’s on the truck and no more wasted trips to the supply house.

Is my business too small for inventory software? When is the right time to start?

You don’t need a massive warehouse or a huge fleet to benefit from an inventory system. The right time to start is when you feel the pain of your current method. If you’re spending hours on manual counts, losing track of parts, or running out of stock at critical moments, your business is ready. Starting early, even when you’re small, helps you build good habits and creates a scalable foundation that will support your growth without the chaos.

How is this different from the inventory features already in my field service software?

That’s a great question. While many field service platforms have basic inventory modules, they often treat materials management as an afterthought. Dedicated inventory software is built to handle the entire lifecycle of your materials—from purchasing and receiving to tracking stock across multiple trucks and warehouses. It offers more robust features for managing suppliers, setting automated reorder points, and providing detailed cost analysis, giving you much deeper control over the financial health of your jobs.

How long does it typically take to get a new inventory system up and running?

The timeline really depends on the cleanliness of your existing data. The software setup itself is usually quick, but the most important step is getting your parts list and current counts into the system. If your data is organized in a spreadsheet, you can often be up and running in a few days. If you’re starting from scratch, it might take a bit longer. Many companies offer support to help you through this initial data migration to make the process as smooth as possible.

How can I be sure this software will actually save me money?

Think about the hidden costs you’re already paying. Every emergency run to a supplier costs you fuel and a technician’s billable time. Every part you over-order is cash tied up on a shelf. Inventory software provides a return on investment by giving you the data to stop this waste. It helps you make smarter purchasing decisions, reduces time spent on manual counts, and ensures your techs have what they need to finish jobs faster, which directly impacts your profitability.