The most obvious costs in your business are easy to spot, but it’s the hidden ones that quietly drain your profits. Think about the money tied up in overstocked parts collecting dust in the warehouse, or the premium you pay for last-minute rush orders. Consider the billable hours lost every time a technician makes an unplanned trip to the supply house. These aren’t just the costs of doing business; they are symptoms of a disconnected inventory process. Without a clear, real-time view of your materials, you’re forced to make expensive guesses. The right construction inventory management software gives you the control to stop the bleeding, turning unpredictable expenses into predictable profitability.

Key Takeaways

- Spreadsheets Can’t Provide Real-Time Clarity: Manual tracking leads to costly mistakes like last-minute supply runs and inaccurate job costing. Dedicated software gives you a live view of your inventory, helping you control costs and keep projects on schedule.

- Choose Tools That Work Where You Do: Your software is only effective if your team actually uses it. Prioritize solutions with a simple mobile app for the field and seamless integrations with the accounting and field service platforms you already rely on.

- Make Your Software a Habit, Not a Hassle: The real value comes from consistent, daily use. A successful rollout involves a clear implementation plan, proper team training, and making the software the single source of truth for all material management.

Why You Need Construction Inventory Software

If you’re running your inventory on a spreadsheet, you’re not alone. It’s the go-to starting point for many businesses. But as you grow, that trusty spreadsheet starts to show its cracks. What was once a simple list becomes a tangled web of outdated numbers, broken formulas, and guesswork. You start spending more time managing the spreadsheet than managing your materials.

This is the point where you have a choice: keep patching a system that’s holding you back or move to a tool built for the job. Making the switch to dedicated inventory software isn’t just about getting organized; it’s about building a more resilient, profitable, and scalable business. It’s about giving yourself and your team the clarity needed to do your best work without the constant stress of material mix-ups.

Are You Facing These Inventory Headaches?

Does this sound familiar? A technician is on-site, ready to finish a job, but they’re missing a single, critical part. Now they have to make an unplanned trip to the supply house, wasting billable hours and pushing back the entire day’s schedule. Or maybe your office phone rings constantly with techs asking what’s in the warehouse or on another truck. These aren’t just minor annoyances; they’re symptoms of a broken process. When you don’t have a real-time view of your stock, projects don’t run smoothly. You end up with inaccurate job costing, frustrated technicians, and unhappy customers. Good inventory management is the foundation of an efficient operation.

Uncover the Hidden Costs of Manual Tracking

The frustrations of manual tracking are obvious, but the hidden costs are what really impact your bottom line. When you don’t know exactly what you have, you’re likely bleeding money in ways you haven’t even considered. You might be overstocking, tying up thousands of dollars in cash on parts that just collect dust. Or you’re understocking, leading to expensive rush orders and lost productivity. Every untracked part that gets lost, damaged, or misplaced is a direct hit to your profits. Tracking your inventory in detail helps you control costs and keep projects on budget, turning guesswork into predictable profitability.

Let’s Bust Some Common Software Myths

Thinking about software can bring up some common worries, but many of them are based on outdated ideas. The biggest myth is that it’s too expensive and only for large corporations. Years ago, that might have been true, but the rise of flexible, cloud-based applications has changed the game. Modern solutions are affordable and allow you to pay only for what you need. Another concern is that it’s too complicated. The truth is, today’s platforms are designed with you in mind—they’re intuitive and built for teams in the field. With the right partner, you can get set up and see a return on your investment faster than you think.

Learn more about how south-Florida based Kyle Plumbing transformed it’s inventory management with Ply.

Key Features Your Construction Inventory Software Must Have

When you start comparing software, the sheer number of options can feel overwhelming. To cut through the noise, focus on the core features that will actually make a difference in your day-to-day operations. The right platform isn’t just a digital list of your parts; it’s a command center for your materials. Here are the non-negotiable features your construction inventory management software must have to truly support your business and help it grow.

Track Your Inventory in Real Time

Knowing exactly what you have and where it is—right now—is the foundation of solid inventory control. Real-time tracking eliminates the guesswork that leads to frantic supply house runs and costly project delays. When your tech pulls a part from their truck, the system should update instantly. This level of accuracy means you can confidently schedule jobs, knowing the necessary materials are on hand. It transforms your inventory from a source of stress into a reliable asset. A system that provides a live view of your inventory and truck stock is essential for keeping projects on schedule and customers happy.

Equip Your Team with Mobile Access

Your team isn’t sitting behind a desk, so your inventory system shouldn’t be stuck there either. Mobile access is a must-have. It empowers your technicians to update inventory levels, check for parts, and even request materials directly from the job site using their phone or tablet. This immediate flow of information keeps everyone in the loop, from the field to the office. It reduces errors, cuts down on back-and-forth communication, and gives your team the tools they need to be more self-sufficient and efficient. When your crew can manage materials on the go, your entire operation becomes more flexible and responsive.

Connect with Your Existing Tools

The last thing you need is another piece of software that doesn’t talk to your other systems. An effective inventory solution should feel like a natural extension of the tools you already rely on. Look for seamless integrations with your field service management software, like ServiceTitan or Jobber, and your accounting platform, such as QuickBooks. When your inventory system syncs automatically, you eliminate double data entry and ensure consistency across your entire business. This connection streamlines everything from job costing and invoicing to purchasing, creating a single, reliable source of truth for your operations.

Automate Your Purchasing Process

Stop letting purchasing be a reactive fire drill. The right software can help you get ahead by automating the process. Look for a system that can monitor your stock levels across all locations—the warehouse and every truck—and automatically create purchase orders when materials run low. You can set minimum quantities for critical parts to ensure you never run out unexpectedly. This proactive approach not only prevents stockouts and project holdups but also frees up your team from the tedious task of manual PO creation. It’s about making your purchasing process smarter, not harder.

Generate Insightful Reports

Data is one of your most valuable assets, but only if you can make sense of it. Your inventory software should do more than just hold numbers; it needs to provide clear, insightful reports. You should be able to easily see where your materials are, how quickly they’re being used, what they cost, and their total value. This information is critical for accurate job costing, identifying slow-moving stock, and making smarter purchasing decisions. With comprehensive reporting, you can spot trends, control costs, and understand the real return on your investment in both materials and software.

Set Secure User Permissions

Not everyone on your team needs access to every piece of information. To protect your data and prevent costly mistakes, your software must allow you to set custom user permissions. This feature lets you control who can see what and who can make changes. For example, you might want your technicians to be able to view and use parts from their truck stock but not see overall inventory costs or place purchase orders. Setting these boundaries ensures that team members only have access to the information relevant to their roles, which maintains data integrity and adds a crucial layer of security to your operations.

Top Construction Inventory Software Platforms (and What Makes Them Different)

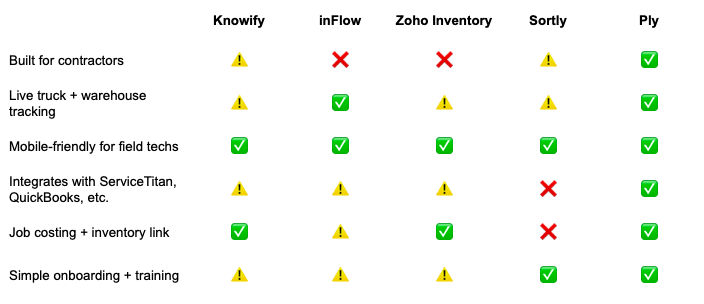

If you’re researching inventory management tools for your construction business, you’re not short on options. But not all software is created equal—especially when it comes to the specific challenges contractors face in managing truck stock, job-site usage, and warehouse inventory. Below, we break down five leading platforms, starting with Ply, which was built specifically for contractors.

Knowify

Knowify is a strong option for companies focused on connecting inventory usage to job costing. It tracks how materials affect project budgets in real time, which helps with estimating and profitability. However, it leans more toward project management than hands-on inventory control, and may not offer deep field-team visibility or mobile-first workflows.

inFlow Inventory

A versatile inventory system used across many industries, inFlow offers strong stock tracking features, barcode scanning, and support for complex setups. It’s best for contractors who need detailed control and don’t mind configuring it to fit their workflow. It doesn’t offer out-of-the-box integrations with contractor software, so it may require extra steps to fully adapt to the trades.

Zoho Inventory

Zoho Inventory is part of the larger Zoho ecosystem, which includes tools for accounting, CRM, and more. It’s useful if you already use other Zoho apps and want everything under one roof. But because it’s not tailored to construction, it may miss the mark for field use or job-site inventory management.

Sortly

Sortly is known for its simplicity and visual interface. It’s easy to set up and use, especially for small teams. You can track inventory with photos and manage parts from your phone, but it lacks deeper features like purchase automation, reporting, and integrations—making it a better fit for lightweight tracking needs.

Ply

Ply is built from the ground up for trade contractors like HVAC, plumbing, and electrical businesses. It provides real-time visibility into inventory across trucks and warehouses, automates purchasing, and integrates seamlessly with tools like ServiceTitan, Housecall Pro, and QuickBooks. Its mobile-first design empowers field techs while giving the office team the control and reporting they need to manage costs and scale operations. With Ply, your entire materials workflow—from purchase order to job-site usage—lives in one connected system.

Explore pricing plans or take a product tour

Legend: ✅ = Strong support, ⚠️ = Partial support, ❌ = Not built for this

How To Pick the Right Construction Inventory Solution

Picking the right inventory software is a big decision, but it doesn’t have to be overwhelming. Think of it less like buying a tool and more like hiring a key team member—one that will work 24/7 to keep your operations running smoothly. The best fit for your business goes beyond a long list of features. It’s about finding a system that solves your specific problems, works for your crew, and can grow with you. To find the right solution, you’ll want to look at your decision from a few key angles: your current needs, your team’s workflow, your future goals, your budget, and your implementation plan.

1. Assess Your Business Needs

Before you even look at a demo, grab a notepad and map out your current inventory headaches. Are parts going missing from trucks? Is your purchasing process a mess of phone calls and paper receipts? Be specific about the problems you need to solve. This list will become your guide. As you evaluate options, look for software that offers the core features you can’t live without. This includes real-time tracking to see what you have on hand, mobile access for your techs in the field, and purchase order management to streamline buying. Make sure it also has strong reporting capabilities to give you clear insights into your material usage and costs.

2. Consider Your Team and Training

The most powerful software in the world is useless if your team finds it clunky or confusing. Your crew in the field and the staff in the office need a tool that feels intuitive and makes their jobs easier, not harder. When you’re looking at different platforms, ask yourself: “Can my team actually use this?” Look for a clean, simple interface. It’s also crucial to get your team on board by explaining why this change is happening. The right software partner will offer solid training and support to get everyone comfortable. When your team understands how the system helps them avoid stockouts and finish jobs faster, they’ll be much more likely to embrace it.

3. Plan for Future Growth

The software you choose today should be able to support your business in two, five, or even ten years. You might only have five trucks now, but what happens when you have fifteen? A scalable solution is essential. Look for flexible plans that allow you to add users, locations, and features as your company expands. Another key piece of future-proofing is integrations. Your inventory system shouldn’t operate in a silo. Ensure it can connect seamlessly with the accounting and field service management software you already use, like QuickBooks or ServiceTitan, to create a single, unified workflow across your entire business.

4. Set Your Budget

It’s easy to assume that powerful inventory software comes with a hefty price tag, but that’s often not the case. Don’t just look at the monthly subscription cost; think about the return on investment. How much money will you save by reducing material waste, eliminating unnecessary purchases, and cutting down on administrative hours? A good system should pay for itself. Use an ROI calculator to get a clearer picture of the potential savings. Look for transparent pricing without sneaky setup fees or long-term contracts. The right software is an investment in your business’s efficiency and profitability, not just another expense.

5. Map Out Your Timeline

Once you’ve chosen your software, you’ll need a clear plan to get it up and running. A smooth rollout doesn’t happen by accident. Start by mapping out the key steps: migrating your existing parts list, performing a full initial count of your warehouse and truck stock, and setting up your new purchasing workflows. Work with your software provider to establish a realistic timeline. Some companies even offer hands-on help with onsite implementation to make sure your warehouse is organized and your data is accurate from day one. A little planning upfront will prevent major headaches down the road and ensure your team can start seeing the benefits right away.

How to Get Your New System Up and Running

You’ve done the research and picked your software. High five! But the real work—and the real payoff—starts now. Implementing a new system can feel like a huge project, but breaking it down into manageable steps makes all the difference. This isn’t just about installing software; it’s about changing how your team manages materials for the better. A smooth rollout sets the stage for long-term success, helping you reduce waste, streamline purchasing, and get a clear picture of your inventory from day one. Think of this as building the foundation for a more efficient and profitable business. We’ll walk through the key phases, from initial setup and data migration to team training and performance tracking, so you can feel confident every step of the way.

1. Start the Initial Setup

First things first: get the software configured for your business. This means setting up your inventory locations, like your main warehouse and each of your service trucks. You’ll also want to create user accounts for everyone on your team, assigning permissions based on their roles. For example, your technicians might only need to see the stock on their truck, while your warehouse manager needs a full view of everything. This initial setup is crucial because it ensures the software reflects how your business actually operates, making it easier for your team to adopt. It’s all about creating a digital version of your physical inventory world.

2. Migrate Your Data Seamlessly

Before you can track anything, you need to get your current inventory data into the new system. This is the perfect opportunity for a fresh start. Instead of just importing that old, messy spreadsheet, begin with a full physical inventory count. Yes, it takes time, but it ensures your starting numbers are accurate and helps you identify any missing or misplaced items right away. Once you have a clean, reliable count, you can import your parts list, supplier information, and current stock levels. A clean data migration prevents headaches down the road and gives you a trustworthy baseline to work from.

3. Train Your Team for Success

A new tool is only as good as the people using it. Getting your team on board is one of the most important parts of the process. Start by explaining why you’re making this change—how it will make their jobs easier, reduce frustrating stockouts, and help the company grow. Provide hands-on training that’s tailored to different roles. Your field techs need to know how to log parts used on a job, while your purchasing manager needs to master the reordering process. Consistent training and support will help everyone feel comfortable and confident with the new system. Consider a partner who offers onsite warehouse implementation to get your team up to speed quickly.

4. Develop Your New Workflows

Now it’s time to build the new software into your daily routines. Map out how your team will handle key tasks like receiving shipments, transferring parts between trucks, and processing returns. The goal is to have one central system for all things inventory. This is where integrations become incredibly powerful. When your inventory software talks to your accounting and field service platforms, you eliminate double entry and create a seamless flow of information from the field to the office. Document these new processes so everyone is on the same page and your operations run smoothly.

5. Track Your Performance from Day One

How do you know if your new system is working? By tracking your results. From the moment you go live, start monitoring key performance indicators (KPIs). Look at metrics like inventory turnover rate, the value of your current stock, and how often you run out of critical parts. Tracking these numbers will show you exactly how the software is impacting your business, from reducing carrying costs to improving job profitability. It also helps you spot areas for improvement over time. Use an ROI calculator to see the financial benefits and prove the value of your investment to your team and stakeholders.

Getting your new inventory management software up and running is a huge step, but it’s just the beginning. The real magic happens when you weave the tool into your daily operations and use its insights to make smarter decisions.

Make the Most of Your Construction Inventory Software

Getting your new inventory management software up and running is a huge step, but it’s just the beginning. The real magic happens when you weave the tool into your daily operations and use its insights to make smarter decisions. Think of it as moving into a new workshop—the space is ready, but now you have to organize your tools and build great habits to do your best work. This is where you turn your software investment into a real competitive advantage, making projects run smoother and saving money in the process.

Adopt These Daily Best Practices

Consistency is your best friend. Making the software a core part of your team’s daily routine ensures you get accurate, real-time data you can trust. Start by making it a rule that all materials leaving the warehouse or a truck are scanned out immediately. The same goes for receiving new stock. This simple habit keeps your records correct and makes sure projects run smoothly without last-minute scrambles for parts. Encourage your techs to use the mobile app to check stock levels before heading to a job. These small, consistent actions create the accountability and accuracy you were missing with spreadsheets and help you fully utilize the features you invested in.

Avoid These Common Pitfalls

It’s easy to fall back into old habits, but that’s the quickest way to undermine your new system. The most common pitfall is creating a “shadow inventory” system by keeping a separate spreadsheet on the side. This defeats the purpose of having a single source of truth. Another mistake is skipping regular cycle counts because you assume the software is always 100% correct. While it’s far more accurate than manual methods, regular counts are still essential for catching misplaced items or theft. Finally, don’t ignore the data. Failing to forecast demand or analyze inventory costs means you’re leaving money on the table. You can even use an ROI calculator to see how these small mistakes add up.

Optimize Your System Over Time

Your business isn’t static, and your inventory system shouldn’t be either. As you gather more data, you can start fine-tuning your operations. Regularly review reports to identify your fastest-moving parts and which ones are collecting dust. Use this information to adjust your reorder points and safety stock levels to free up cash and warehouse space. As your company grows, explore more advanced features or new integrations that can connect your inventory system with your accounting or field service software. This continuous optimization ensures the software grows with you, helping you become more efficient and profitable over time.

Know Where to Find Support

Even the most intuitive software comes with a learning curve, so don’t hesitate to ask for help. Your software provider should offer a range of support options. Start with their online knowledge base or video tutorials for quick answers to common questions. For more complex issues, reach out to their customer support team via email, chat, or phone. A good partner wants to see you succeed and will be happy to walk you through a feature or help you solve a problem. Hearing from other businesses like yours can also be incredibly helpful, so check out testimonials to see how they’ve overcome similar challenges and found success.

Related Articles

- Smart Inventory Management Tips for Field Service Teams

- Contractor Inventory Management Simplified

- Inventory Management Archives

- Truck Stock Management Basics: Auditing, Barcoding, and Organization

- How Tariffs and Supply Chain Costs Are Driving Up Prices for Skilled Trades—and How Inventory Management Can Help

Frequently Asked Questions

How much time and effort does it really take to switch from a spreadsheet to inventory software?

The initial setup does require a focused effort, especially the first physical count of your inventory. However, a good software partner will guide you through the process, and many offer hands-on help to get your warehouse organized. Think of it as a one-time project that pays you back with countless hours saved in the long run. Once you’re up and running, the daily management is far quicker and more accurate than wrestling with a spreadsheet ever was.

My technicians are used to doing things their own way. How can I get them to actually use a new system?

Adoption is all about showing your team how the software makes their job less frustrating. When they realize a mobile app can tell them exactly which truck has the part they need, saving them a trip to the supply house, they’ll see the value. The key is choosing an intuitive, mobile-friendly system and providing clear training that focuses on their daily tasks. When the tool genuinely helps them finish jobs faster, they’ll be on board.

I’m worried about the cost. How do I know if this is a smart financial move for my business?

It’s helpful to shift your thinking from a cost to an investment. Consider the money you’re currently losing from untracked parts, over-ordering, and the billable hours your techs waste on material runs. Good software directly addresses these issues. It gives you the data to stop buying materials you don’t need and ensures you’re accurately costing every job. The right system should pay for itself by closing these financial leaks and improving your overall profitability.

I already use other software to run my business. Will this just create more work?

Quite the opposite. The right inventory software should reduce your workload by connecting with the tools you already use, like your accounting or field service platform. When your systems are integrated, information flows automatically. For example, when a tech uses a part on a job, it can be instantly added to the invoice without anyone having to enter it manually. This eliminates double entry and ensures your data is consistent everywhere.

What’s the biggest mistake to avoid when we first get started?

The most common mistake is carrying old, messy data into your new system. It’s tempting to just import your existing spreadsheet to save time, but this often brings inaccuracies with it. The best thing you can do is start with a clean slate by performing a full, physical count of your entire inventory—in the warehouse and on every truck. This ensures your data is trustworthy from day one and sets you up for long-term success.