If you run a contracting or trades business, you already know how quickly inventory can turn into a daily headache. Inventory management tools are supposed to make this easier by helping you keep tabs on stock across your warehouse, shop, trucks, and job sites. The right software should prevent you from running out of materials, piling up excess inventory, or losing track of orders. Those problems hit cash flow fast and leave customers waiting.

Search online for something like “software inventory management tools,” and you’ll find plenty of platforms that reviewers love. Most of them are built for e-commerce brands, wholesalers, or large retailers. For contractors and trades, the real question is not which system has the longest feature list. It’s the system that actually fits the way you work. Modern software inventory management tools offer automated reordering, barcode scanning, real-time tracking, and even AI forecasting. Those features only matter if they help you keep trucks stocked, jobs moving, and purchasing under control without adding extra admin work.

This guide breaks down what software inventory management tools do, the features that matter most for contractors, and how leading platforms, including Ply, compare so you can choose a solution that fits your business instead of forcing your business to fit the software.

Key Takeaways

- Inventory management tools help you track stock and automate reordering, so you don’t get stuck with too much or too little on hand.

- The best systems play nice with your sales channels, warehouses, and accounting software, giving you a real-time look at what’s where.

- Pick your inventory software based on your company’s size, industry, and whether you just need basic tracking or want to go all-in on automation.

Understanding Software Inventory Management Tools

Inventory software lets you track stock, manage orders, and keep supply chain chaos in check—all without living in spreadsheets. These tools have changed a lot: what started as clunky paper ledgers and Excel sheets is now a world of real-time data, automation, and cloud dashboards you can check from your truck.

Definition and Evolution

Inventory management software? Basically, it’s a digital system that tracks your stuff (raw materials, parts, finished goods) across every step, from ordering to final sale. It keeps an eye on what comes in, what goes out, and what’s just gathering dust.

Back in the day, folks used paper ledgers or, later, basic spreadsheets. Then came dedicated inventory software with barcode scanning. Now, you’ve got barcode and RFID systems, cloud-based platforms, and integrations with accounting and sales tools. Some even use AI to forecast demand and reorder automatically, which is wild if you think about it.

Modern inventory management tools connect with the rest of your business software, giving you a bird’s-eye view of stock across multiple locations. AI-driven platforms can even predict when you’ll run low and kick off purchase orders before you realize you need them.

Key Objectives and Benefits

The main point? Keep the right stuff in stock at the right time. If you overstock, you tie up cash and space; if you run out, you’re losing jobs and trust. These systems help you dodge both headaches.

With better stock control, you cut carrying costs and get real-time visibility into inventory, no matter where it’s stashed. Automated reorder points mean you don’t get caught empty-handed when a big order comes in.

Inventory management software boosts efficiency in order fulfillment and helps you deliver on time—stuff your customers will definitely notice. It also makes financial planning easier, since you finally have reliable inventory valuation data. If you’re selling through multiple channels, syncing stock automatically across all those platforms is a game-changer.

Difference Between Inventory Control and Inventory Management

Here’s something that trips people up: inventory control isn’t quite the same as inventory management. Control is about the nuts and bolts—where your materials are, how many you’ve got, and how they move around the warehouse. Management zooms out: it’s about forecasting demand, building supplier relationships, and making smart purchasing decisions.

Think of control systems as answering “Where is this?” or “How many are left in bin 5?” Management systems answer “When do we need to reorder?” or “Which supplier actually delivers on time?” Most decent platforms these days blend both, so you don’t have to juggle a bunch of separate apps.

Core Features of Inventory Management Software

Good inventory software makes it way easier to track stock, process orders, and make decisions based on real numbers—not gut feelings. These core capabilities help you avoid running out of supplies or sitting on a mountain of unused parts.

Real-Time Inventory Tracking Capabilities

With real-time inventory tracking, you see what’s in stock across all your locations, instantly. The software updates quantities as soon as you make a sale, process a return, or receive a shipment. No more waiting for someone to update a spreadsheet at the end of the day (or week, if we’re being honest).

Modern inventory management software syncs your stock across warehouses, shops, and online channels right away. You can check what’s available and where it’s sitting—super handy if you’re running multiple job sites or retail counters.

This kind of visibility means you won’t accidentally oversell or take on a job you can’t fulfill. When someone buys something, the system adjusts inventory everywhere, automatically. Plus, you can spot slow movers or react to sudden spikes in demand before they become problems.

Barcode Scanning and Serial Number Tracking

Barcode scanning speeds things up and cuts down on mistakes. Instead of typing in SKUs or descriptions (and hoping you don’t fat-finger a number), your crew just scans items as they receive, pick, or count them. It’s quicker, and you get fewer headaches from data entry errors.

If you need to track individual items—say, for warranties or compliance—serial number tracking lets you follow each unit from delivery to installation. That’s a lifesaver if you deal with regulated or high-value products.

RFID technology goes a step further, letting you scan hundreds of items in seconds. A warehouse team can sweep through 300+ pieces in under 20 seconds with RFID handhelds. It’s not cheap, but the accuracy is hard to beat. Inventory accuracy gets a big boost with this tech.

Order and Stock Management Functions

Stock management tools help you keep just enough inventory—never too much, never too little. The software watches your reorder points and can create purchase orders as soon as you hit a preset threshold, so you don’t get caught off guard.

Order management features route jobs to the best fulfillment location, factoring in stock availability and shipping distance. If a customer orders from across town, the system picks the closest warehouse with inventory. That saves you both time and money.

Some of the best stock management features:

- Automated replenishment based on sales or usage patterns

- Multi-location transfers to balance stock between warehouses or job sites

- Stock allocation for jobs in the pipeline

- Inventory reservations so you don’t promise what you can’t deliver

All these cut down on manual busywork and help you turn inventory faster.

Reporting and Analytics

Inventory reports tell you what’s working and what’s not. Dashboards show numbers like turnover rate, stock aging, fill rates, and gross margin return on investment. You can see which materials fly off the shelves and which ones just collect dust.

Advanced analytics use your history to forecast what you’ll need next month or next quarter. The system looks at buying trends, seasonality, and even promotions to help you order smarter, so you’re not left with pallets of unused stuff (or, worse, nothing at all).

Automated alerts flag issues before they snowball—low stock, aging inventory, weird return rates, or products about to expire. Managers can jump on these problems right away instead of finding out the hard way during a job or audit.

Advanced analytics use your history to forecast what you’ll need next month or next quarter. The system looks at buying trends, seasonality, and even promotions to help you order smarter, so you’re not left with pallets of unused stuff (or, worse, nothing at all).

Types of Inventory Management Systems

When you’re picking inventory management software, you’ve basically got three flavors: cloud-based, on-premise, and hybrid. Each has its own quirks, so what works for one shop might not work for another.

Cloud-Based Inventory Management

Cloud-based systems run on remote servers—you just log in from any device with internet. No installs, no servers in your back office, and no need for a dedicated IT guy.

Your team can check inventory, process orders, or update records from a phone, tablet, or laptop—wherever they are. That’s a huge plus if you’re bouncing between job sites or managing multiple shops.

Why go cloud?

- Automatic software updates (no more “update required” pop-ups)

- Lower upfront costs—usually just a monthly subscription

- Easy to scale up as you grow

- Real-time data across all your locations

Most cloud-based solutions are perfect for small to mid-sized businesses. They play nice with eCommerce, accounting, and shipping apps. The only real downside? If your internet goes down, you’re stuck waiting.

On-Premise Solutions

With on-premise inventory management, you install the software on your own servers and computers. You own the license and control everything—data, security, customization, you name it.

This setup gives you total control and the ability to tweak things to fit your processes. It’s a good fit if you’ve got strict data privacy needs or work somewhere with spotty internet.

The catch? You’ll spend more upfront on hardware, licenses, and IT staff. Updates, backups, and security are all on you. And getting everything set up takes time—definitely not plug-and-play.

Hybrid Solutions

Hybrid systems mix cloud and on-premise elements. Maybe you keep sensitive data on local servers but use the cloud for day-to-day access and reporting.

This lets you lock down financials or proprietary info while giving your field teams cloud dashboards for real-time updates. For example, a warehouse management system could run locally, while sales teams pull inventory data from the cloud.

Common hybrid setups:

- Local database with cloud-based reporting

- On-premise core system with cloud mobile apps

- Main operations in-house, with cloud backup/disaster recovery

Hybrid systems are flexible but get complicated to set up and maintain. They’re usually best for bigger companies with IT resources and compliance needs.

Top Software Inventory Management Tools in 2025

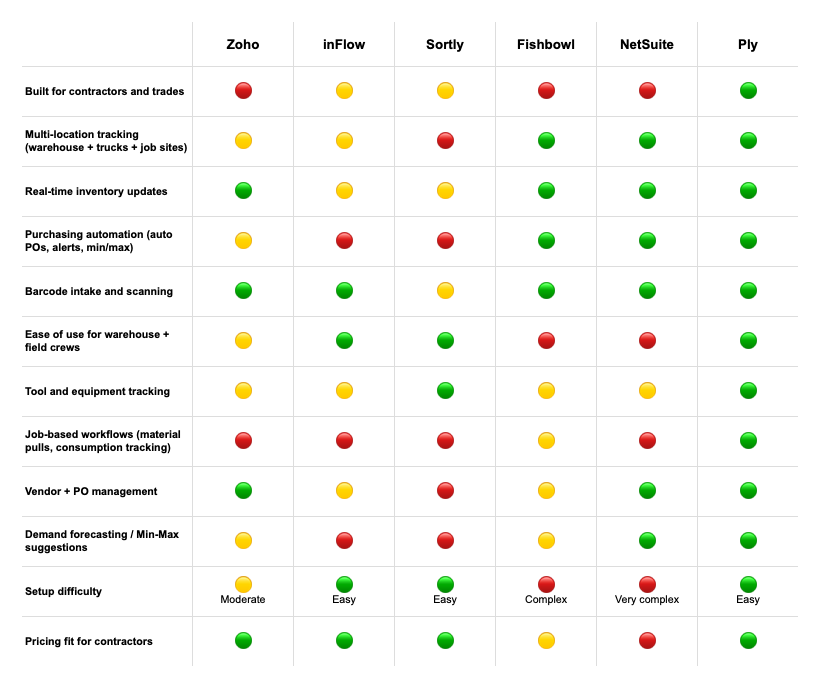

There are a lot of software inventory management tools out there, and each one brings something different to the table. Some work well for manufacturing or e-commerce, others shine in multi-warehouse environments, and only a few actually make sense for contractors and trades. Here is a breakdown of the most common platforms, what they do well, and where they may fall short for field-driven businesses.

Ply

Ply is a procurement and inventory management platform that is built for contractors and growing service businesses. It connects purchasing and inventory in one system so teams can see stock levels and spending in real time. You can manage vendors, track purchase orders, and set automated reorder points that keep materials flowing.

Ply is designed for the way contractors actually work, and it keeps warehouses and trucks on the same page without extra admin work. It is a strong fit if you want something simple that still handles the full workflow.

View Ply pricing or see how it works.

Zoho Inventory

Zoho Inventory is a cloud system that works well for teams that sell across several locations or online channels. It syncs inventory everywhere so you do not oversell, and it gives you barcode scanning, batch tracking, and reporting tools.

Zoho shines for companies with retail or online sales, although it is not built specifically for contractors, and some of its workflows can feel geared toward product sellers rather than service teams.

NetSuite Inventory Management

NetSuite Inventory Management is part of the larger NetSuite ERP suite, and it is designed for large operations with complex supply chains. It offers advanced tools like bin tracking, lot traceability, demand planning, and multi-currency support.

NetSuite is powerful, but it is also heavy and expensive. Many contractors find it more system than they need, and it usually requires an IT team or consultant to set up and maintain.

Cin7

Cin7 gives multi-channel sellers inventory control, point-of-sale capabilities, and B2B order management. It tracks goods from purchase order through sale and can automate replenishment.

Cin7 works well for brands that sell products online and in stores, although its focus on sales channels means it does not always fit how field teams and job-based workflows operate.

Extensiv

Extensiv is built for e-commerce businesses that rely on third-party logistics. It keeps inventory in sync across distributed warehouses, and it routes orders to the fastest and most affordable fulfillment location.

This is a good fit for high-volume shippers. Contractors and trades businesses that do not use 3PLs usually will not need most of what Extensiv offers.

Fishbowl

Fishbowl Inventory combines inventory tracking with manufacturing tools like bills of materials, work orders, and raw material management. It syncs with QuickBooks and can track lots and serials across multiple warehouses.

Fishbowl is strong for manufacturers. Its manufacturing-first design can feel complex if you only need to track consumables, truck stock, and job site inventory.

inFlow

inFlow is an easy-to-use platform for small and mid-sized businesses that want simple inventory tracking, purchase orders, and barcode scanning without lots of configuration. It offers basic reporting and straightforward workflows.

Because it keeps things simple, some companies outgrow inFlow once they need multi-location control, automated purchasing, or deeper field workflows.

Odoo Inventory

Odoo Inventory is part of Odoo’s open-source suite that lets you bolt on additional modules for CRM, invoicing, and sales. It offers warehouse tools, automated replenishment, and order tracking.

Odoo can be flexible, although it usually requires technical skills to set up and customize. Contractors without IT help may find the system difficult to configure or maintain.

Square for Retail

Square for Retail ties point-of-sale activity directly to inventory so every sale updates stock levels automatically. It works well across several retail locations and gives visibility into product movement.

Square’s strength is in brick-and-mortar retail. Contractors that do not run retail stores may find the inventory functionality too limited for job-based workflows.

Sortly

Sortly is a visual inventory app that uses photos and QR codes to help teams track tools, equipment, and materials. The mobile-first setup is easy to learn, and it is great for quick scanning and field updates.

Sortly is simple, which is a plus, although it does not offer deeper purchasing workflows, automated reordering, or multi-location controls that growing contractors often need.

QuickBooks Commerce (formerly TradeGecko)

QuickBooks Commerce handles inventory, orders, B2B e-commerce, and multi-currency transactions. It ties inventory changes directly to QuickBooks so your financials stay in sync.

It works well for small product-based businesses, although companies that rely on field crews or multi-location stock usually need more flexibility than Commerce provides.

Essential Integrations for Inventory Management Tools

Let’s be honest: if your inventory software doesn’t play nice with your other business systems, you’re going to have headaches. Integrating with accounting keeps your books straight, POS integration means real-time inventory, and linking up with third-party logistics helps you manage orders and warehouses without losing track.

Accounting Platforms

When you connect your inventory tool with accounting software, you stop wasting time on double entry and avoid those annoying financial discrepancies. With inventory and accounting in sync, stock changes hit your general ledger right away, so your COGS, revenue, and inventory values stay up to date—no manual work required.

QuickBooks integration is a lifesaver for small and midsize companies. When inventory moves or gets adjusted, it posts right to your financials. This speeds up month-end and cuts down on mistakes from copy-pasting numbers.

It also gives you better info to make decisions. Accountants can see real-time inventory values when making reports or cash flow forecasts. Production teams get a clearer view of costs for raw materials and finished goods, since everything’s tied together.

Point-of-Sale Systems

If you integrate your point-of-sale system, your inventory stays accurate as you make sales. When someone buys something at the register, your inventory drops instantly—no more overselling or awkward phone calls to customers.

Retailers with several locations can see inventory across all their stores. If you run out at one place, you can check if another has it. Customers get accurate info whether they shop online or in-store.

Sales data flows into your inventory system, helping you spot fast movers and tweak reorder points. This helps you avoid tying up cash in dead stock while still keeping shelves full. It’s just practical.

Third-Party Logistics (3PL)

Third-party logistics (3PL) providers take care of warehousing and shipping when you’d rather not. With 3PL integration, you can actually see what’s in those outside warehouses. Stock updates automatically as things move in and out.

When orders arrive, the system can route them to the best warehouse based on what’s in stock and shipping costs. This speeds up fulfillment and can save you money. Managing multiple 3PLs from one dashboard is a relief if you’ve ever tried to juggle them manually.

Customer service improves, too. Your team can track shipments and give real delivery estimates without logging into half a dozen portals. Returns are easier, since inventory updates as soon as products come back in.

Warehouse and Multi-Location Inventory Management

If you keep materials in more than one place, you need software that shows you what you have and where it is. For contractors, that usually means a mix of warehouse stock, shop supplies, truck inventory, and materials sitting on active job sites. The right system should help you stay organized across all of them so nothing gets lost or forgotten.

Warehouse Management Basics That Matter

Warehouse tools should help you receive materials, track what comes in, and keep counts accurate without slowing your team down. With modern systems, you can scan items during intake, move materials to the right shelf or bin, and update counts in real time. This cuts down on mistakes and keeps everyone on the same page.

Contractors do not need complicated warehouse robotics or route-optimization software. What they actually need is a simple way to see what is on the shelf, what just arrived, and what needs to be restocked. Ply supports fast intake with barcode scanning and clear visibility into every item in your warehouse.

Multi-Location Inventory Tracking for Contractors

Most inventory systems are built for retailers or manufacturers, but contractors have a different challenge. Materials do not just stay in a warehouse. They move constantly between trucks, job sites, and the shop. Multi-location tracking keeps all of that connected.

A good system should update stock levels the moment something is used or moved so you can see shortages coming before they slow down a job. Ply tracks warehouse inventory, truck stock, shop supplies, and job site materials. When you transfer items between locations or consume materials on a job, Ply updates your counts instantly.

This gives you a single, accurate view of inventory everywhere. You can see what each truck has, what each job requires, and whether your warehouse is running low so you can restock before it becomes an issue.

Advanced Capabilities and Automation

Modern software inventory management tools do more than store counts. They take manual work out of your day and help you make smarter purchasing decisions so you are never scrambling for materials at the last minute.

Workflow Automation That Saves Time

Automation keeps contractors from getting buried in admin work. The right system should create purchase orders when you are running low, send alerts when stock is about to run out, and update inventory levels automatically when materials are received or used.

Ply automates these everyday workflows so your team spends less time chasing paperwork and more time doing actual work. When stock hits your preset minimums, Ply can alert you or create a purchase order based on your rules. When materials arrive at the warehouse, barcode scanning updates counts instantly.

Smarter Forecasting and Reordering

Guessing how much material you need is one of the fastest ways to tie up cash or slow down jobs. Demand forecasting gives you a clearer idea of what you will need so you can stay ahead.

Ply includes smart Min/Max capabilities that help you understand usage patterns and reorder at the right time. The more the system learns about your purchasing and consumption trends, the better it gets at dialing in the right inventory levels.

Supplier and Purchasing Management

Building good vendor relationships saves money and prevents delays. You need a place to track purchase orders, see what is open, and compare vendor performance.

Ply centralizes your purchasing so you can see order history, delivery timing, and costs across all vendors. When you reorder a material, you can use your preferred supplier or switch to a backup if needed.

Simple Kitting and Material Grouping

Many contractors organize materials into install kits or bundles so techs and field crews leave with everything they need. Ply supports simple grouping workflows so you can bundle materials together and track them as a set without complicated manufacturing tools.

Choosing the Best Inventory Management Software

Finding inventory management software that actually fits your business means weighing the features that matter, thinking about how it’ll grow with you, and making sure it works for your specific industry headaches.

Key Evaluation Criteria

The best inventory management software brings together features that make a real difference day-to-day. Real-time inventory tracking is the backbone. You want to see stock levels across every location, right when you need them—not hours later.

Integration is a big one. The system should play nice with your e-commerce, accounting, and shipping tools, ideally without a mess of third-party connectors. If you’re dealing internationally, multi-currency support isn’t optional—it’s a must.

Automated reordering saves time and keeps you from running out of key items. The software should track supplier lead times and spit out purchase orders automatically when stock dips too low. Barcode scanning and mobile access make warehouse work faster and cut down on fat-finger mistakes.

Reporting and analytics tools show you what’s working and what’s not. You need visibility into metrics like turnover rates, carrying costs, and profitability. And please—make the interface simple enough that your crew can actually use it without a week of training.

The system should play nice with your e-commerce, accounting, and shipping tools, ideally without a mess of third-party connectors. If you’re dealing internationally, multi-currency support isn’t optional—it’s a must.

Scalability and Business Fit

Let’s be real: small shops don’t need the same bells and whistles as a giant retailer. If you’ve got one warehouse and 50 SKUs, don’t get stuck with a bloated system built for the big guys.

Cloud-based inventory management software solutions give you room to grow. Higher-tier plans unlock unlimited users and locations. It’s worth checking how they price things—per user, per transaction, or just a flat fee.

Your system needs to keep up as business picks up. If you’re planning to expand, make sure it supports multiple warehouses, batch tracking, and serial number management. You’ll thank yourself later when things get more complicated.

Industry-Specific Needs

Every industry brings its own curveballs. Food and beverage? You need expiration and lot tracking for recalls. Manufacturing? Bill of materials and production planning are non-negotiable.

If you’re selling online, look for software that syncs inventory across all your sales channels—no more overselling headaches. Wholesale and B2B? You’ll want customer-specific pricing, bulk orders, and quoting tools. Importing? Make sure it handles customs docs and foreign-trade zones.

Retailers need point-of-sale integration and in-store pickup management. If you use third-party logistics, seamless links to fulfillment and shipment tracking are key—or you’ll be chasing info all day.

Implementation Practices and Future Trends

Rolling out inventory management software isn’t just plug-and-play. You need a plan for data transfer and getting your team on board. After launch, keep an eye on how the system’s actually performing. Tech keeps moving fast—what works now might look dated in a year or two.

Data Migration and System Adoption

Moving your old inventory data into new software takes more than a few clicks. Start by cleaning your data—scrub out duplicates and junk before you even think about importing.

Usually, you’ll export from your old system into CSV or Excel files, then map those fields into the new system so everything lands where it should. Test with a small chunk of data first to catch any weirdness before you do the full migration.

Getting your team to actually use the new system? That’s half the battle. Hands-on training helps, and quick reference guides or cheat sheets go a long way. Appoint a couple of go-to people in each department so folks aren’t left floundering.

Many companies run the old and new systems side by side for a few weeks. This overlap lets you double-check accuracy and gives everyone time to get comfortable before you flip the switch for good.

Performance Monitoring and Optimization

Keep tabs on key metrics to see if your inventory software is pulling its weight. Stock accuracy should hit at least 95% when you compare physical counts to what’s in the system.

Order fulfillment speed tells you how long it takes from order to shipment. Check this weekly—slowdowns creep in fast if you’re not watching. Inventory turnover shows how quickly you’re moving product out the door.

Don’t ignore system speed. If pages take more than three seconds to load, users get frustrated and work slows down. Sometimes a little database tune-up or a server upgrade fixes that.

Regular audits can uncover features you’re paying for but not using. Most folks only tap into 40-60% of what their software can do. Stay on top of vendor updates for bug fixes and new features—you might find something that makes life easier.

Emerging Trends in Inventory Management

- Artificial intelligence and machine learning are shaking up how companies forecast demand and manage stock. These tools can even analyze product images and sensor data to catch defects before they hit your customers. Pretty wild, right?

- Automated mobile robots now zip around warehouses using smart sensors—no fixed tracks needed. They work alongside your crew to move goods faster and speed up order fulfillment.

- Predictive picking software uses your sales history and upcoming promos to guess what customers will order next. You can start picking before the orders even roll in, which is honestly a game-changer.

- Third-party logistics partners make it possible to outsource warehousing and shipping without building your own infrastructure. These setups work best when your systems talk to each other so the supply chain runs like a single unit.

Frequently Asked Questions

Choosing the right inventory management tool isn’t always straightforward. You’ve got to weigh features, costs, how well everything integrates, and whether your data stays secure. Here are some of the big questions contractors and trades businesses keep running into:

What features should be considered when selecting an inventory management tool?

Real-time inventory visibility is a must. You want software that syncs stock across all warehouses, stores, and online channels so nobody’s working with old info.

Demand forecasting with predictive analytics helps you avoid both overstocking and running out. The system should use your sales history, current trends, and seasonality to nail down what to buy and when.

Multi-channel sync is crucial if you’re selling on more than one platform. When something sells, inventory updates everywhere automatically—no more overselling surprises.

Barcode and RFID support speeds up stock handling and cuts down on errors. RFID can scan hundreds of items in a flash with almost no mistakes.

Automated replenishment saves time by kicking off purchase orders as soon as stock drops below your set point. The system should draft orders, recommend quantities, and flag low inventory before it’s a problem.

Detailed dashboards and reports give you a clear view of aging stock, fast and slow movers, fill rates, and trends. Automated alerts help you jump on issues before they turn into real headaches.

How can small businesses benefit from free inventory management software?

Small businesses can finally track every unit without needing a big staff. Automation helps you dodge cash-flow crunches from overbuying or running out of popular items.

Free tools beat spreadsheets hands down—less manual error, more visibility. Even the basic stuff is way better than juggling paper or disconnected files.

Most of these tools grow with you. Start simple, then add more features as your orders pick up.

The software helps small businesses cut costs by avoiding over-purchasing and trimming storage bills. With better visibility, you only buy what you need and move inventory out faster.

Are there any software inventory management tools suitable for large-scale enterprises?

Large businesses need software that plugs into ERP, accounting, and POS systems. These tools give you a single source of truth across all your sites and sales channels.

Enterprise systems support ABC and XYZ analysis to sort products by demand and value. That way, you can budget smarter and clear out dead stock instead of letting it gather dust.

Warehouse automation and smart putaway features boost productivity for big operations. The software maps out picking routes, suggests storage spots, and handles batch orders with ease.

Vendor management and procurement controls get more important as you scale. Advanced systems centralize vendor info, track performance, automate approvals, and stay on top of lead times across hundreds of suppliers.

Multi-location management lets you see and control inventory across dozens of warehouses and stores from one dashboard. The system routes orders to the best spot based on what’s in stock and where it needs to go.

What are the advantages of using a cloud-based inventory management system?

Cloud-based systems let your team access inventory from anywhere with a connection—perfect for remote work or when you’re out on a job site.

Automated backups keep your stock and financial data safe without you lifting a finger. The cloud provider handles maintenance, updates, and security so you don’t have to sweat it.

Cloud software usually costs less than old-school on-premise setups. You pay a subscription instead of shelling out for servers and hardware.

Scaling up is a breeze on cloud platforms. Add users, locations, or features as you grow—no major IT headaches.

Cloud systems use encryption and role-based access to keep your data locked down. Big-name data centers generally do a better job with security than most contractors can manage in-house.

How does an inventory management tool integrate with other business systems?

Modern systems offer API-based integrations with POS, eCommerce, and accounting tools. This keeps your orders, sales, and inventory synced in real time—no more double entry.

ERP integrations give you a unified view of business operations. Inventory data flows straight into financials, purchasing, and production planning without manual effort.

Marketplace integrations connect directly to Amazon, eBay, Shopify, and others. When an order comes in, the system updates inventory and kicks off fulfillment automatically.

Shipping integrations handle label creation and tracking updates. The inventory system gets shipment confirmations and updates stock locations as soon as things move.

Accounting software connections mean sales, returns, and inventory values flow right into your financials. No more copy-pasting numbers or chasing down mistakes.

What security measures should be in place for software-based inventory management systems?

Role-based access control lets your crew see only what they need. Warehouse folks pull up picking lists, while managers dive into financials and forecasts. Keeps things tidy and, frankly, less stressful.

Encrypted databases keep sensitive stuff—like pricing, vendor contacts, and sales numbers—locked down. You want real encryption, both when your data’s sitting there and when it’s zipping across the internet.

Multi-factor authentication? Yeah, it’s a pain sometimes, but it throws up a solid wall against most hacks. Instead of just a password, users confirm their identity with another device or method before they get in. Worth it.

Regular automated backups save your bacon when things go sideways. Cloud-based systems usually handle this for you, backing up several times a day. Still, it’s smart to double-check your backup plan now and then.

Audit trails let you see exactly who changed what. If someone tweaks inventory counts, approves a purchase order, or updates product info, you’ll have a record. It’s not about mistrust—it’s just good business.

User activity monitoring helps you spot weird behavior before it turns into a problem. The system should log login attempts, data exports, and permission changes so you can review them if something feels off.