How much money is hiding in that pile of leftover materials in your warehouse? What’s the real cost of a project delay caused by a single missing part? These aren’t just minor inconveniences; they are significant financial leaks that silently drain your profitability. When you lack a clear, real-time view of your materials and tools, you’re likely losing money to waste, theft, and inefficiency. The right technology isn’t just another expense—it’s a strategic investment in your bottom line. By implementing a dedicated inventory management software, tailored for the construction industry, you can plug these leaks, gain control over job costs, and turn wasted dollars into profit.

Key Takeaways

- Choose software built for construction realities: Generic tools can’t handle the complexity of multiple job sites, service trucks, and warehouses. Prioritize a system with real-time, multi-location tracking, a simple mobile app for your field team, and integrations with your existing accounting software.

- Focus on ROI, not just the price tag: The right software pays for itself by solving expensive problems. Calculate its value based on its ability to prevent over-purchasing, eliminate project delays from stockouts, and stop the costly loss of tools and equipment.

- Plan for a smooth team adoption: The best features are useless if your team won’t use them. Select a system that fits your current needs and create a clear implementation plan with dedicated training to ensure everyone is on board from day one.

Why Is Construction Inventory Management So Different?

If you’ve ever tried to manage your materials with a generic spreadsheet or a tool built for retail, you already know the headache. Construction inventory isn’t about tracking products on a shelf in a single stockroom. It’s a completely different game with its own set of rules.

Unlike a typical store, construction companies have to track parts, materials, and tools across a constantly shifting landscape of job sites, storage yards, service trucks, and warehouses. One day a pallet of drywall is in the main warehouse; the next, it’s split between three different project sites across town. This decentralized nature makes it incredibly difficult to know what you have and where it is at any given moment. This complexity is why specialized material management software is so critical for optimizing how your business handles its stock.

Furthermore, your inventory isn’t just a list of items—it’s directly tied to project timelines and budgets. Running out of a specific fitting doesn’t just mean a backorder; it can cause costly project delays that ripple through your entire schedule. Effective inventory management in construction is also about cost control. You need tools that can help you manage costs effectively by preventing over-purchasing, reducing material waste, and ensuring you have the right parts for the job without tying up cash in excess stock. It’s a delicate balance that standard inventory systems just aren’t built to handle.

Key Features for Construction Inventory Software

When you’re looking for the right inventory software, it’s easy to get lost in a long list of features. But for construction and trade businesses, a few capabilities are non-negotiable. The right tool isn’t just about counting parts; it’s about connecting your office, warehouse, and field teams so that every job runs smoothly. A generic retail inventory system just won’t cut it when you’re managing materials across multiple trucks and active job sites.

Your software should solve your biggest headaches, like surprise stockouts, misplaced tools, and confusion about what materials are where. It needs to be tough enough for the job site but simple enough for your whole team to use without a steep learning curve. As you evaluate your options, focus on these core features that deliver the most impact for contractors. These are the functions that will save you time, cut down on waste, and ultimately help you complete more jobs on time and on budget.

✅ Real-Time Materials Tracking Across Sites

Your inventory isn’t sitting neatly in one stockroom. It’s in the main warehouse, on service trucks, and at multiple job sites. Without a central system, figuring out what you have and where it is becomes a full-time job of phone calls and guesswork. The best construction inventory software gives you a real-time, bird’s-eye view of all your materials and equipment, no matter their location.

This means you can instantly see if a technician has the right part on their truck or if you need to order more copper wire for a project starting next week. This level of visibility prevents unnecessary purchases and last-minute runs to the supply house, keeping your projects on schedule and your budget intact. A clear view of your inventory and truck stock is fundamental to efficient operations.

✅ Mobile Access for Your Field Team

Your technicians are the ones on the front lines. If they can’t easily access inventory information from their phone or tablet, the system will fail. Requiring them to call the office to check stock or fill out paper forms at the end of the day creates bottlenecks and frustration. A user-friendly mobile app is essential.

With mobile access, your field team can check parts out from their truck, see what’s available at the warehouse, and even request materials for an upcoming job, all from the job site. This empowers them to work more efficiently and independently, reducing administrative burdens and ensuring they always have what they need to get the job done right the first time. It closes the loop between the field and the office, making everyone’s job easier.

✅ Automated Low-Stock Alerts

Running out of a critical part mid-job is a nightmare. It brings work to a halt, causes project delays, and forces expensive, unplanned trips to the supplier. Manual inventory checks are time-consuming and prone to error, making it easy to miss dwindling stock levels until it’s too late. That’s where automated alerts come in.

Good inventory software lets you set minimum quantity thresholds for your most important items. When stock drops below that level, the system automatically notifies you or your purchasing manager. This proactive approach ensures you can reorder materials before you run out, preventing costly downtime. It turns your inventory management from a reactive scramble into a smooth, predictable process, which has a direct impact on your bottom line.

- PRO TIP: You can calculate the ROI of preventing just a few stockouts/month.

✅ Integrate with Your Existing Software

Your inventory management system shouldn’t be an island. It needs to communicate seamlessly with the other software you rely on to run your business, especially your accounting and field service management platforms. Manually entering data between systems is a recipe for errors, wasted time, and inaccurate financial reporting.

Look for a solution with robust integrations for tools like QuickBooks, ServiceTitan, or Jobber. When your inventory software syncs with your other systems, parts used on a job can be automatically added to the invoice, and purchase orders can be reconciled with your accounting records effortlessly. This creates a single source of truth for your business, streamlines workflows, and gives you a much clearer picture of job profitability.

✅ Use Barcode Scanning for Asset Tracking

Manually tracking every tool, piece of equipment, and box of materials is tedious and inaccurate. A misplaced digit can throw off your entire count. Barcode or QR code scanning transforms this process, making it fast, simple, and incredibly accurate. Your team can use their smartphone’s camera to scan items in and out of the warehouse or a service truck.

This creates a clear digital trail for every asset, so you always know who has what and where it is. It drastically reduces the time spent on manual data entry and minimizes the risk of human error. For valuable tools and equipment, barcode scanning is essential for preventing loss and theft. It also simplifies cycle counts and audits, turning a dreaded task into a quick and painless process.

The Best Inventory Software for Construction Companies

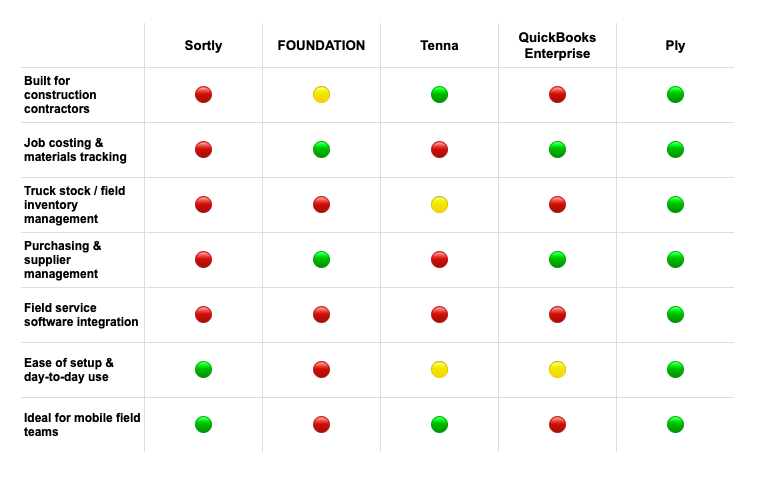

Finding the right inventory software can feel like a huge task, but it doesn’t have to be. The best tool for your business depends on your specific needs—from the size of your team to the complexity of your projects. Some platforms are great for simple, visual tracking, while others offer deep financial integrations and enterprise-level control. We’ve reviewed the top options to help you see what’s out there and find a system that helps you manage materials, control costs, and keep your projects running smoothly. Let’s look at some of the leading contenders in the construction space.

1. Ply: The All-in-One Materials Management Platform

Ply is built from the ground up for contractors who need to simplify how they buy and manage materials. It’s more than just an inventory tracker; it’s a complete system for your entire procurement process. You can manage everything from warehouse stock and truck inventory to purchase orders and supplier relationships in one place. What makes Ply stand out is its focus on creating efficient workflows that save you time and money. It also offers powerful integrations with the software you already use, like ServiceTitan, Jobber, and QuickBooks, connecting your field operations directly to your back office and accounting. If you’re looking for a comprehensive platform to streamline your entire materials lifecycle, Ply is designed for you.

2. Sortly: Simple, But Too Basic for Construction

Sortly wins points for being easy to use and highly visual, but its simplicity is also its limitation. It’s great for keeping tabs on tools or small assets, but it lacks the purchasing, job costing, and integration capabilities construction companies rely on. For tracking consumables, materials, and complex workflows across multiple job sites, Sortly quickly runs out of steam. It’s better suited for light tool tracking than full-scale materials management.

3. FOUNDATION: Powerful, but Built for the Back Office

FOUNDATION is a robust, enterprise-grade system with serious reporting and financial features. It’s a good fit for large construction firms with dedicated accounting departments—but it’s overbuilt for most small or mid-sized contractors. The interface can feel dated, the learning curve steep, and the pricing reflects its enterprise focus. If you’re looking for something your field teams can actually use day to day, FOUNDATION may be too complex to justify the investment.

4. Tenna: Strong on Equipment, Weak on Materials

Tenna is a capable platform for tracking heavy equipment and tools. It shines when you need maintenance logs, GPS tracking, and dispatch scheduling. But when it comes to managing construction materials, it’s limited. The system was built primarily for fleet and asset management, so the purchasing, job costing, and consumable tracking features that contractors need are secondary. Tenna’s a good add-on for equipment-heavy operations, not a standalone solution for materials management.

5. QuickBooks Desktop Enterprise: Broad, but Not Built for Construction Inventory

QuickBooks Enterprise is a reliable all-in-one business management system, and many contractors already use it for accounting. However, its inventory module is built for general businesses—not construction workflows. It lacks the depth needed for managing supplier relationships, purchase orders, and field inventory. While QuickBooks is great for job costing and financial visibility, it doesn’t connect your warehouse, trucks, and job sites in real time. It’s an accounting-first tool trying to handle a materials-first problem.

Other Tools to Consider

Ultimately, your best system depends on what slows you down today. If your biggest bottlenecks are tied to tracking truck stock, reconciling purchase orders, or managing supplier pricing, you’ll benefit most from a platform built specifically for contractors. Ply sits in that sweet spot—comprehensive enough to manage complex construction operations, but simple enough that your field teams actually use it.

How Inventory Software Cuts Construction Costs

Adopting inventory software is about more than just getting organized—it’s a direct strategy for protecting your bottom line. When you don’t have a clear view of your materials, tools, and equipment, you’re likely losing money in ways you haven’t even realized. Think about the last-minute runs to the supply house, the mystery of where that expensive new drill went, or the pile of unused materials sitting in the corner of your warehouse. These small leaks add up to significant financial drains.

Inventory management software transforms your process from reactive to proactive. Instead of guessing what you need or scrambling when a part is missing, you have real-time data to make informed decisions. This visibility allows you to control spending, streamline operations, and accurately forecast for future jobs. By implementing a system to track every item from the warehouse to the job site and back, you can plug those financial leaks and see a tangible impact on your profitability. You can even use an ROI calculator to estimate how much you could save. It’s about making every dollar you spend on materials count.

Prevent Over-Purchasing and Material Waste

It’s easy to fall into the trap of over-ordering “just in case,” but that habit ties up cash in materials you don’t need yet. Inventory software gives you a precise look at your stock levels across all locations, so you can stop guessing and start buying with confidence. By tracking material usage on a per-job basis, you can see exactly what was used and what was left over, helping you refine your purchasing for future projects. This prevents the accumulation of dead stock and eliminates the high costs and project delays associated with last-minute emergency buys.

Reduce Project Delays from Stockouts

Nothing brings a job to a screeching halt faster than a missing part. When a technician is on-site and realizes they don’t have the right valve or fitting, the entire project timeline is thrown off. This doesn’t just waste your team’s time; it costs you money in unproductive labor and can damage your relationship with the client. A good inventory system helps you manage your materials by providing real-time visibility into your truck and warehouse stock. With automated low-stock alerts, you can reorder essential items before you run out, ensuring your team always has what they need to keep the project moving forward.

Minimize Tool and Equipment Loss

Tools and equipment are major investments, but they have a tendency to “walk away” from job sites or get left behind in the shuffle. Inventory software with asset tracking capabilities puts an end to the mystery. By assigning each tool to a specific technician, truck, or job site using barcodes or QR codes, you create a clear chain of custody. This accountability drastically reduces loss and theft. Instead of constantly spending money to replace expensive equipment, you can protect the assets you already own and ensure they are available for the next job.

Improve Budgeting and Cost Tracking

How accurately can you track material costs for each job? If you’re relying on receipts and manual data entry, chances are you’re missing the full picture. Inventory software gives you precise job costing by tracking every part and material allocated to a project. When your inventory system integrates with your accounting software, this data flows seamlessly, eliminating manual work and reducing the risk of human error. This allows you to create more accurate estimates, understand the true profitability of each job, and make smarter financial decisions for your business.

How Much Does Construction Inventory Software Cost?

Let’s talk about the price tag. When you’re running a business, every dollar counts, and investing in new software is a big decision. The cost of construction inventory software can range from free to thousands of dollars per year, depending on the features you need and the size of your operation. Instead of just looking at the sticker price, it’s helpful to think about the cost in terms of the value it brings back to your business. The right tool isn’t an expense; it’s an investment that pays for itself by cutting waste, saving time, and helping you book more jobs.

Free vs. Paid Tools

You might be tempted to start with a free tool, and for a one-person shop just getting started, that can be a decent first step. However, free plans are often limited in features, the number of users, or the amount of data you can store. A better approach is to take advantage of free trials. Many companies offer a trial that lets you explore all the features of a paid plan without any commitment. This gives you a real feel for how the software can simplify your inventory management before you spend a dime. For a growing business, a paid tool is almost always the right move for better support, security, and features that scale with you.

Understanding Subscription Models

Most inventory software operates on a subscription model, typically billed monthly or annually. The pricing structure can vary quite a bit between platforms, so it’s important to understand what you’re paying for. Some tools charge per user, while others might charge per vehicle or asset. For example, you might see plans starting around $49 per month for a set number of users, or pricing based on your fleet size, like $7 per vehicle per month. These different models allow you to find a plan that fits your specific business size and needs, so you’re not paying for features you won’t use.

Calculating ROI for Your Business Size

The real question isn’t “How much does it cost?” but “How much will it save me?” The return on investment (ROI) is where these tools truly shine. One contractor reported that using inventory software cut the time spent searching for misplaced materials by 15 hours a week. What could you do with that extra time? That’s less time your techs spend running to the supply house and more time on billable work. By preventing over-purchasing, reducing project delays from stockouts, and minimizing tool loss, the software quickly pays for itself. Access a free online ROI calculator to see exactly how much your business could save.

A small, nimble crew has very different needs than a large-scale operation with multiple warehouses and dozens of job sites running at once. The key is to find a solution that solves your current problems without creating new ones, and that can grow with you.

How to Choose the Right Construction Inventory Software

Picking the right inventory software isn’t a one-size-fits-all decision. The best tool for your business depends entirely on your team’s size, the complexity of your projects, and where you see your company heading in the next few years. A small, nimble crew has very different needs than a large-scale operation with multiple warehouses and dozens of job sites running at once. The key is to find a solution that solves your current problems without creating new ones, and that can grow with you.

Think about your day-to-day operations. Are you struggling to keep track of tools on a couple of trucks? Or are you trying to manage a complex supply chain with materials flowing between a central warehouse and numerous active projects? Answering these questions will help you zero in on the features that matter most. Below, we’ll break down what to look for based on the size of your team, so you can find a system that feels like it was built just for you.

For Small Teams

If you’re running a small team, your top priorities should be simplicity, accessibility, and affordability. You don’t have time for a complicated system that requires weeks of training. You need a tool that your crew can start using from any device, anywhere. Look for software with a clean, intuitive interface and a strong mobile app that allows your team to track materials and equipment on the go. This is crucial for preventing expensive tools from getting lost or left behind. The goal is to find a straightforward system that helps you track inventory across a few job sites and trucks without adding unnecessary complexity to your workflow.

For Mid-Sized Companies

As your company grows, so do your inventory challenges. Mid-sized businesses need more than just basic tracking; you need a system that helps you control costs, reduce waste, and avoid those last-minute, overpriced material runs. This is where features like automated low-stock alerts and detailed reporting become essential. You need software that gives you up-to-date information on what you have, where it is, and its value, so you can make smarter purchasing decisions. At this stage, it’s also vital to consider how the software integrates with your other tools, like your accounting or field service management platforms, to create a more connected and efficient operation.

For Large Operations

For large-scale operations, inventory management becomes a major logistical puzzle. You’re tracking parts, materials, and tools across multiple job sites, storage yards, and warehouses. Your software needs to be powerful enough to handle this complexity. Look for a system that offers robust multi-location management to prevent over-purchasing and ensure you have optimal stock levels everywhere. Advanced features like customizable user permissions, detailed analytics, and streamlined purchasing workflows are non-negotiable. As your company adapts to broader industry trends, you need a flexible platform that can support your operational strategies for years to come.

How to Implement Your New Inventory Software

Choosing the right software is the first step, but a successful rollout is what truly transforms your operations. A thoughtful implementation plan ensures your team adopts the new system smoothly and you start seeing a return on your investment quickly. By focusing on planning, training, and tracking, you can set your business up for long-term efficiency and growth.

Plan Your Setup and Data Migration

Before you move anything into your new system, take the time to map out your entire inventory process. This is your chance for a fresh start. Begin by cleaning up your existing data—whether it’s in spreadsheets or an old system—to ensure you’re not carrying over outdated information. Decide how you’ll organize your materials, tools, and equipment. Will you categorize by job type, supplier, or something else? You can gain complete control over your inventory by defining locations like your main warehouse, specific job sites, and even individual trucks. A clear plan for data migration makes the transition from old methods to a new, streamlined workflow much smoother.

Train Your Team for a Smooth Rollout

Your new software is only as good as the team using it. Getting everyone on board is critical for a successful launch. Start by identifying a few key team members—like your warehouse manager and lead technicians—to become your internal experts. A good software partner will provide excellent training and support to make this process easier. Schedule dedicated training sessions and use the resources provided, like tutorials and support docs. Set clear expectations for how and when the software should be used, from checking out tools in the field to updating stock levels in the warehouse. When your team understands the “why” behind the change and feels confident using the new tool, adoption happens naturally.

Measure Success with the Right Metrics

How do you know if your new system is actually working? By tracking the right metrics. Before you launch, benchmark your current performance. How much time do your techs spend searching for materials each week? What’s your average material waste per job? Once the new software is up and running, you can measure the improvement. Look for reductions in misplaced materials, fewer last-minute supply runs, and better budget accuracy.

Common Mistakes to Avoid When Choosing Inventory Software

Picking the right software can feel like a huge decision, but you can make the process a lot easier by sidestepping a few common tripwires. Knowing what not to do is just as important as knowing what to look for. Let’s walk through some of the most frequent mistakes businesses make so you can choose your new system with confidence.

First, many businesses stick with spreadsheets for far too long. While they might work when you’re just starting out, they quickly become a source of errors and inefficiencies as you grow. Manual data entry leads to mistakes, and it’s nearly impossible to get a real-time view of your stock. Another common pitfall is assuming all inventory software is the same. A solution built for a retail shop won’t understand the complexities of managing materials across multiple job sites and service trucks. You need a tool designed for the trades.

It’s also a mistake to overlook how your team will actually use the software. If a system is clunky or difficult to learn, your technicians won’t adopt it, no matter how powerful its features are. Prioritize software with a user-friendly interface and solid training and support. Finally, don’t forget about the big picture. Your inventory system shouldn’t operate in a silo. Failing to consider integration capabilities with your accounting and field service software can create data bottlenecks and manual work. Choose a system that not only solves today’s problems but is also scalable enough to grow with your business for years to come.

Related Articles

- 5 Best Construction Inventory Management Software

- 6 Best Accounting Software for Inventory Management 2025

- Inventory Management Software: The Ultimate Guide

Frequently Asked Questions

My team is used to doing things the old way. How do I get them on board with using new software?

That’s the million-dollar question, isn’t it? The key is to make it clear how the software makes their job easier, not harder. Start by involving your key field and warehouse staff in the selection process. When they have a say, they’re more invested. Focus your training on the specific tasks they do every day, like checking out a part from their truck, instead of overwhelming them with every single feature. Show them how a quick scan on their phone saves them from filling out paperwork or making a frustrating call back to the office. When they see it as a tool that saves them time and headaches, adoption will follow naturally.

My business is still small. Do I really need dedicated inventory software right now?

It’s smart to question big investments when you’re small, but think of it this way: establishing good habits now is much easier than trying to fix messy, chaotic ones later. Even with just a few trucks, you’re likely losing time and money to misplaced tools or last-minute supply runs. Starting with a simple, scalable system helps you build a foundation for growth. It allows you to track job costs accurately from the beginning and ensures that as you add more trucks and employees, your operations stay smooth instead of becoming a major bottleneck.

What’s the real difference between inventory management and asset tracking?

It’s a great question because the terms are often used together. Think of it like this: inventory management is for the things you use up and sell, like copper fittings, wire, and PVC pipe. The goal is to track quantities, manage stock levels, and streamline purchasing. Asset tracking is for the valuable, reusable items you own, like drills, ladders, and heavy equipment. The focus here is on knowing where each specific item is, who is using it, and when it needs maintenance to prevent loss and theft. A good system will handle both for you.

How long does it typically take to get a new system up and running?

The timeline really depends on the complexity of your inventory and how much data you’re bringing over. For a smaller company with a clean list of materials, you could be up and running in a matter of days. For larger operations with thousands of parts across multiple locations, you should plan for a few weeks to properly migrate data, set up locations, and train your team. The most important thing is not to rush the setup. Taking the time to clean up your data and plan your warehouse layout beforehand will make the actual transition much faster and smoother.

Besides just tracking parts, what’s the single biggest benefit I’ll see?

While knowing where your parts are is a huge win, the biggest benefit you’ll likely see is in your job costing. When you can accurately track every single part and material used on a specific job, you get a crystal-clear picture of your true profitability. This moves you beyond guesswork and allows you to create smarter, more competitive estimates for future work. It transforms your inventory from a simple list of items into powerful financial data that helps you make better business decisions.