Every part sitting on a shelf or in a truck represents cash. When those parts are disorganized, misplaced, or overstocked, it’s like having your money tied up in a messy back room. The hidden costs of poor material management—from wasted technician time to inaccurate job quotes—can quietly eat away at your profit margins. To protect your bottom line, you need to treat your inventory with the same precision you apply to your finances. This is precisely what inventory and warehouse management software is designed to do. It helps you optimize your stock levels, reduce waste, and ensure every dollar spent on materials directly contributes to a profitable job, turning a major expense into a streamlined asset.

Key Takeaways

- Move from Chaos to Control: Great software solves your biggest inventory headaches, like last-minute supply runs and money tied up in unused parts, by giving you real-time visibility into your warehouse and trucks.

- Demand Seamless Integration: Your inventory software must connect effortlessly with your existing field service and accounting platforms. This eliminates manual data entry and creates a unified workflow, ensuring your job costing and invoicing are always accurate.

- Plan Your Rollout and Prove Its Worth: A successful transition requires a clear implementation plan and team buy-in. After launch, track key metrics like inventory accuracy and order fulfillment to measure your return on investment and confirm the system is saving you time and money.

What Makes Great Inventory and Warehouse Management Software?

Choosing the right software can feel like a huge task, but it boils down to one thing: finding a tool that makes your life easier and your business more profitable. Great inventory and warehouse management software isn’t just about tracking what’s on the shelves; it’s about creating a smooth, efficient system that connects your warehouse, your trucks, and your office. It gives you the clarity to make smart purchasing decisions, stop wasting money on misplaced materials, and get your techs what they need to finish jobs on time. Let’s break down what a truly great system looks like and what it should do for your contracting business.

What It Should Do for You

At its core, this software should give you complete control and visibility over your materials. Think of it as the single source of truth for everything you own. It tells you exactly which parts you have, where they are (in the warehouse or on a specific truck), and how many are left, in real time. This accuracy is the foundation for a more efficient operation. A good system helps you streamline your entire supply chain—from ordering materials from suppliers to getting them into your technicians’ hands. It transforms inventory from a constant headache into a well-oiled part of your business that supports growth instead of holding it back.

Problems This Software Should Solve

If you’re constantly dealing with stockouts that delay jobs, or you have thousands of dollars tied up in parts that are just collecting dust, you’re facing common inventory challenges. A great software solution tackles these problems head-on. It helps you move from a reactive state—like making emergency runs to the supply house—to a proactive one. By analyzing your usage data, it can help you forecast future demand, so you always have the right parts on hand without overstocking. It also solves the mystery of vanishing materials by tracking every item from purchase to installation, reducing shrinkage and keeping your inventory counts accurate.

Must-Have Features for Contractors

For contractors, generic software just won’t cut it. You need features built for the way you work. Real-time inventory tracking is non-negotiable, especially for managing truck stock, so your techs know exactly what they have on board. Look for robust purchasing and order management tools that simplify your material purchasing. The best systems also offer barcode scanning to speed up receiving and cycle counts. Most importantly, your software needs to be a central hub that integrates seamlessly with the accounting and field service management platforms you already use, like QuickBooks or ServiceTitan. This ensures data flows smoothly across your entire business.

Spreadsheets vs. Software: What’s the Real Difference?

Many businesses start with spreadsheets, and that’s understandable. But as you grow, the cracks start to show. Spreadsheets are prone to human error, can’t provide real-time updates, and make it nearly impossible for your team to collaborate effectively. The real difference with dedicated software is control and automation. It turns a chaotic, manual process into a streamlined system that automatically updates information. While a spreadsheet might seem free, the hidden costs of inaccurate data, wasted time tracking down parts, and delayed jobs add up quickly. The right inventory management solution is an investment that pays for itself by giving you precision and efficiency.

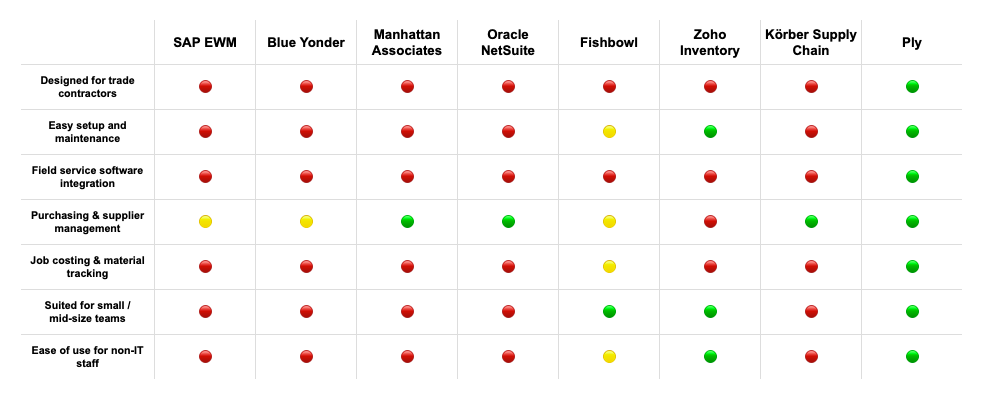

The Top Inventory & Warehouse Software, Compared

Choosing the right system can feel like a full-time job—but it doesn’t have to be. Here’s a look at some of today’s leading inventory and warehouse management platforms, from enterprise giants built for global supply chains to practical tools that actually work for contractors and service teams. The goal: help you find software that fits how your business runs day-to-day, not one that forces you to adapt to it.

Ply

Ply is purpose-built for contractors in the trades, and that focus makes all the difference. It streamlines material buying, tracking, and job costing without adding unnecessary layers. Designed for plumbing, HVAC, and electrical businesses, Ply handles everything from supplier orders and warehouse stock to what’s on each technician’s truck. Its ready-made connections with ServiceTitan, Housecall Pro, and Jobber tie inventory directly to your jobs and invoices—so you spend less time reconciling spreadsheets and more time completing profitable work. It’s simple where you need it, powerful where it counts, and built around how service businesses actually operate.

SAP Extended Warehouse Management (EWM)

SAP’s Extended Warehouse Management (EWM) is one of the most advanced warehouse systems available—but it’s built for global manufacturers and massive distribution centers, not local service teams. It delivers sophisticated automation and scalability for complex supply chains but often requires months of configuration, expensive consulting, and dedicated IT staff to maintain. For contractors or mid-sized operations, EWM’s simply over-engineered and cost-prohibitive—more likely to slow you down than help you move faster.

Blue Yonder

Blue Yonder focuses on predictive analytics and AI-driven logistics, which can be transformative for large distribution networks. But its enterprise scope comes at a price: high implementation costs, steep learning curves, and heavy reliance on data scientists or specialized admins. For trade businesses that just need to know what parts they have, where they are, and when to reorder, Blue Yonder is far more system than the job demands.

Manhattan

Manhattan’s supply chain platform unifies inventory, labor, and automation—but it’s built with major retailers and high-volume warehouses in mind. The system’s depth and customization require significant IT involvement and ongoing optimization. Smaller companies often find it too rigid and complex to adapt to everyday service workflows. For trades that value flexibility and ease of use, Manhattan’s sophistication quickly turns into unnecessary friction.

Oracle NetSuite

NetSuite’s all-in-one ERP covers inventory, accounting, CRM, and ecommerce—great for enterprises seeking a single platform, but overkill for anyone focused primarily on materials and job tracking. Its breadth makes it expensive, difficult to configure, and dependent on consultants for updates. For service contractors, much of NetSuite’s functionality sits unused while they still wrestle with basic inventory visibility and purchase order management.

Fishbowl

Fishbowl appeals to small businesses ready to graduate from QuickBooks alone, offering automation and real-time inventory data. But its age is showing—Fishbowl’s interface can feel dated, integrations limited, and scaling options thin once your operation grows. It’s a solid starter system but often becomes a stopgap as companies outgrow its feature set and flexibility.

Zoho Inventory

Zoho Inventory is an accessible option for growing businesses, especially those already using other Zoho apps. Yet its simplicity is also its ceiling. It handles stock tracking across multiple locations but lacks deep purchasing controls, job costing, and the field-service connectivity that trades rely on. For contractors managing inventory tied to specific jobs, Zoho ends up feeling more like a sales tool than an operational system.

Körber Supply Chain

Körber’s warehouse management platform offers excellent mobile features and configurability, but it’s still an enterprise-grade system at heart. Implementation is technical, customization is extensive, and costs can climb fast. Körber shines in large warehouse networks but isn’t built for smaller teams that need straightforward workflows and easy onboarding for field staff.

How to Choose the Right Inventory & Warehouse Management Software

Picking the right software can feel like a huge decision, because it is. This tool will become the backbone of your material management, influencing everything from your team’s daily efficiency to your company’s bottom line. The goal isn’t just to find a digital replacement for your spreadsheets; it’s to find a partner that simplifies your operations and supports your growth.

Think about what you truly need. Are you struggling with disorganized truck stock? Do you need a better way to handle purchase orders? Are you losing money on unaccounted-for materials? The right software addresses your specific pain points head-on. It should feel less like another task to manage and more like a central hub that connects your inventory, purchasing, and even your accounting. When you find a system that fits your workflow, you’ll spend less time fighting fires and more time focusing on the work that actually makes you money.

What to Look For

When you start comparing options, look for a system that acts as a central command center for your materials. The best inventory & warehouse management software brings together inventory tracking, order management, and purchasing into one unified platform. For contractors, this means you can see what’s in the warehouse, what’s on each truck, and what’s on order from a single screen. This visibility is crucial for preventing costly delays and last-minute runs to the supply house. Also, look for features designed for the trades, like multi-location tracking for warehouses and trucks, and the ability to create and manage purchase orders efficiently.

Does It Play Well with Your Other Tools?

Your business already runs on a set of essential tools, whether it’s field service software like ServiceTitan or accounting software like QuickBooks. A new inventory system shouldn’t force you to live on a digital island. The most critical question to ask is: does it integrate with the software I already use? A seamless integration means data flows automatically between systems, eliminating double entry and reducing human error. When your inventory platform can talk to your field service and accounting software, you get a complete picture of your business, from job costing to final invoicing, without the manual patchwork.

Understanding the True Cost

The sticker price of a software subscription is only one piece of the puzzle. To understand the true cost, you need to look at the total investment required. This includes potential one-time setup or implementation fees, the cost of any new hardware like scanners or tablets, and the time your team will spend on training. A thorough cost-benefit analysis will help you compare the total expenses against the expected gains, like reduced material waste, fewer emergency purchases, and improved technician efficiency. Getting a clear picture of all potential costs upfront ensures there are no surprises down the road and that the investment aligns with your budget and business goals.

Free vs. Paid: Is It Worth the Investment?

You might see free inventory tools out there, and for a one-person operation just starting out, they can be a temporary fix. These tools usually offer basic tracking but lack the features a growing trade business needs. As you add technicians, trucks, and jobs, you’ll quickly run into their limitations. Paid software is an investment in your company’s efficiency and scalability. It offers robust features like advanced reporting, dedicated customer support, and crucial integrations that free tools simply can’t match. Think of it as the difference between a basic hand tool and a power tool—both can get a job done, but one is built for professional results.

Calculate Your Return on Investment (ROI)

How do you know if the investment is actually paying off? By measuring your return on investment (ROI). In the trades, ROI from inventory software shows up in several ways: lower carrying costs from reduced overstocking, less shrinkage from lost or misplaced materials, and more accurate job costing because you know exactly which parts were used. You can also measure the time saved by your techs and office staff, who no longer have to track parts or chase down purchase orders manually.

- PRO TIP: Use an ROI calculator to estimate your potential savings and build a business case for making the switch.

A Smooth Rollout: Your Implementation Guide

Choosing your new software is a huge step, but getting it up and running smoothly is what really sets you up for success. A thoughtful rollout can make the difference between a tool that gathers dust and one that transforms your business. The key is to break the process down into manageable steps. Think of it less as a massive overhaul and more as a series of smart upgrades. From planning your first moves to getting your crew excited about the change, a clear strategy ensures everyone is on the same page and ready to go. This approach helps you sidestep common frustrations and start seeing the benefits of your new system much faster.

Create Your Implementation Plan

Before you touch a single piece of software, grab a notepad or open a doc and sketch out a plan. A successful rollout starts with knowing what success looks like for your business. What specific problems are you trying to solve? Do you want to reduce material waste, speed up job costing, or just get a real-time view of what’s on each truck? Write these goals down. Then, create a realistic timeline with key milestones, like when data will be moved over and when training will happen. Assign a point person for the project—someone who can keep things moving and be the go-to for questions. A clear plan is your roadmap to optimizing your inventory management and making sure the transition is as seamless as possible.

Move Your Data Without the Headaches

Getting your existing data into a new system can feel like a massive chore, but a little prep work goes a long way. This is the perfect opportunity for some spring cleaning. Before you migrate anything, review your current data. Are your parts lists accurate? Are supplier contacts up to date? Tidying up this information first prevents you from carrying old problems into your shiny new system. Most modern software solutions are designed to make this process easier, often with import tools for spreadsheets. If you’re feeling overwhelmed, remember that some companies, like Ply, offer hands-on implementation support to help you get all your data moved over correctly without the headaches.

Get Your Team On Board

Your new software is only as good as the people using it. That’s why getting your team’s buy-in from the start is non-negotiable. Begin by explaining why you’re making the change and how it will make their jobs easier—less time searching for parts, fewer frantic calls back to the shop, and more accurate job costing. Involve your senior techs and warehouse manager in the process early on; their feedback is invaluable. Schedule dedicated training sessions and make sure they are hands-on. An organized approach to training, much like an organized warehouse layout, makes day-to-day operations smoother for everyone involved and ensures the new tool gets used to its full potential.

Common Roadblocks and How to Avoid Them

Even with the best plan, you can hit a few bumps. The most common ones are inaccurate data, team resistance, and trying to do too much at once. You can get ahead of these by tackling them head-on. We already talked about cleaning your data, which is your best defense against inaccurate inventory counts—one of the biggest challenges in warehouse management. To handle resistance, focus on the benefits for the team and celebrate small wins as they learn the new system. Finally, avoid scope creep by sticking to your initial goals. Roll out the core features first, let the team get comfortable, and then introduce more advanced functions later.

Keep an Eye on Performance

How do you know if the new system is actually working? You have to measure it. Before you launch, decide on a few key performance indicators (KPIs) to track. These don’t have to be complicated. You could monitor things like inventory accuracy, how long it takes to fulfill a parts request, or the number of return trips to the warehouse. Tracking these numbers will show you where you’re improving and highlight any areas that need more attention. There are many free online tools that can help you calculate your return on investment so you see the financial impact of your new software in clear terms. Regular check-ins on these metrics will help you fine-tune your processes and get the most value from your investment.

How to Know If It’s Working: Key KPIs

You’ve done the hard work of choosing and implementing new software. Now, how do you know if it’s actually making a difference? The answer is in the numbers. Tracking key performance indicators (KPIs) isn’t just about creating reports; it’s about getting a clear, honest look at your operations. It’s how you prove the value of your investment and find new ways to make your business even more efficient.

Think of KPIs as your guideposts. They show you what’s improved, what’s holding steady, and where you might need to adjust your processes. When you have the right software, tracking these metrics becomes much simpler. Instead of digging through spreadsheets and paperwork, you can see your performance at a glance. We’ll walk through a few of the most important KPIs that tell you if your inventory and warehouse management system is truly working for your business.

Track Your Inventory Accuracy

Inventory accuracy is simple: does the number of parts in your system match the number of parts on your shelves and in your trucks? When these numbers don’t line up, you run into expensive problems. You might order materials you already have, or worse, tell a tech a part is in stock when it isn’t, leading to project delays and extra trips to the supplier. Regularly measuring this KPI helps you spot discrepancies before they hurt your bottom line. Good software makes cycle counts and real-time tracking much easier, so your records always reflect reality.

Measure Your Order Fulfillment

How often do your technicians get the exact parts they need for a job on the first try? That’s what your order accuracy rate tells you. A high rate means your team is efficient and your customers are happy. A low rate points to issues in your fulfillment process that lead to return trips, project delays, and frustrated clients. Tracking this KPI shows you how well your warehouse operations support your field team. It’s a direct measure of your ability to get the right materials to the right place at the right time, which is fundamental to running an efficient business.

Gauge Your Operational Efficiency

How long does it take for a part to go from being received at your warehouse to being loaded onto a technician’s truck? This is your pick and pack cycle time, and a shorter cycle means a more efficient operation. When your team can find, pull, and stage materials quickly, your technicians spend less time waiting and more time on billable work. Monitoring this KPI helps you identify bottlenecks in your warehouse workflow. If your cycle time is too long, you can look for ways to organize your stockroom better or streamline your workflows to get parts moving faster.

Monitor Your Cost Savings

Ultimately, new software should improve your profitability. You can measure this by tracking metrics like your receiving cycle time, which reflects the labor cost associated with processing incoming materials. Faster receiving means lower overhead. But the savings go deeper. With better inventory control, you can reduce costly emergency runs to the supply house, take advantage of bulk pricing, and minimize material waste. By tracking these costs before and after implementation, you can calculate the real impact on your finances and see exactly how much the right system is saving you.

Check In on Customer Satisfaction

Your inventory management has a direct impact on your customers, even if they never see your warehouse. The most telling KPI here is your rate of return trips or call-backs due to incorrect or missing parts. Every time a technician has to leave a job site to get a forgotten component, it delays the project and can damage the customer’s confidence. When your team consistently has the right materials on hand, jobs get done faster and more reliably. This leads to happier customers, better reviews, and more repeat business, proving that organized operations are a key part of excellent customer service.

Related Articles

- Contractor Inventory Management Simplified

- Smart Inventory Management Tips for Field Service Teams

- Truck Stock Management Basics: Auditing, Barcoding, and Organization

- Ply optimizes Jobber inventory management

- Inventory Management Archives

Frequently Asked Questions

My business is still small. When is the right time to move from spreadsheets to real software?

The best time to switch is usually right before you feel like you’re drowning in spreadsheets. If you’re starting to experience regular stockouts, your technicians are making extra trips to the supply house, or you can’t get a clear picture of job profitability because you don’t know what materials were used, those are all signs. Think of it less as a question of size and more about complexity. Once you have multiple trucks and technicians to manage, dedicated software stops being a luxury and becomes a tool for smart, sustainable growth.

You reviewed a lot of options. How do I know which software is truly built for a contractor?

Look for software that speaks your language and is designed for your specific workflow. A generic system might be able to track items in a warehouse, but a contractor needs more. Ask if it can manage inventory across multiple trucks in real-time. Check if it simplifies the purchasing process from your actual suppliers. Most importantly, see if it connects directly with the field service and accounting software you already use, like ServiceTitan or QuickBooks. The right fit will feel like it was made for the trades, not adapted for them.

What’s the biggest mistake businesses make when rolling out new inventory software?

The most common pitfall is treating it purely as a technology project instead of a people project. Two things often go wrong: they import messy, outdated data into the new system, which just moves the old problems into a new home. The other is failing to get the team on board early. If your technicians and warehouse manager don’t understand why the change is happening and how it makes their jobs easier, they won’t use it correctly. A little data cleanup and clear communication upfront make all the difference.

I don’t have a dedicated IT department. How much work is this to actually set up?

This is a valid concern for most trade businesses. The setup time really depends on how clean your current data is. The initial work involves organizing your parts lists and counts. However, a good software partner won’t just hand you a login and walk away. Look for a company that offers hands-on implementation support to guide you through moving your data and getting your team trained. With the right support, it’s a manageable project that doesn’t require you to be a tech expert.

Why is it so important that my inventory software integrates with my other tools?

Integrations are what turn a good inventory tool into the central hub of your operations. When your inventory software talks to your field service platform, your technicians can see what parts are on their truck and add them to a job seamlessly. When it talks to your accounting software, that parts list automatically flows into the invoice without anyone having to type it in again. This connection eliminates double-entry, reduces costly errors, and gives you a true, real-time picture of each job’s profitability.