Picture this: It’s Monday. You’ve got an important job at 9:00 a.m., so you head to the warehouse early to grab the parts you need. Suddenly, it’s 8:35 a.m., and you’re still digging through bins, frustrated because you can’t find the right fitting or part number.

It’s an all-too-familiar scenario for contractors. Poor labeling slows jobs, wastes materials, and frustrates techs. The good news? With a few smart labeling strategies and the right tools, you can speed things up, reduce errors, and make your inventory system work for you, not against you.

Let’s break down what good labeling looks like, from quick barcode wins to high-tech NFC tags, plus field-tested tips to keep things running smoothly, whether it’s Monday or any other day of the week.

Start with the Basics: Barcodes and Printed Labels

Printed labels are the foundation of any good inventory management system. They help your team find what they need quickly, avoid mix-ups, and restock faster. But not all labels are created equal.

What to Use and Where

- 1D Barcodes: These are the classic black-and-white lines you see on pretty much everything. Perfect for shelves, bins, and individual parts.

- 2D Barcodes: Think of QR codes. These can hold more data and are useful when you want to link to product manuals, install videos, or reorder pages.

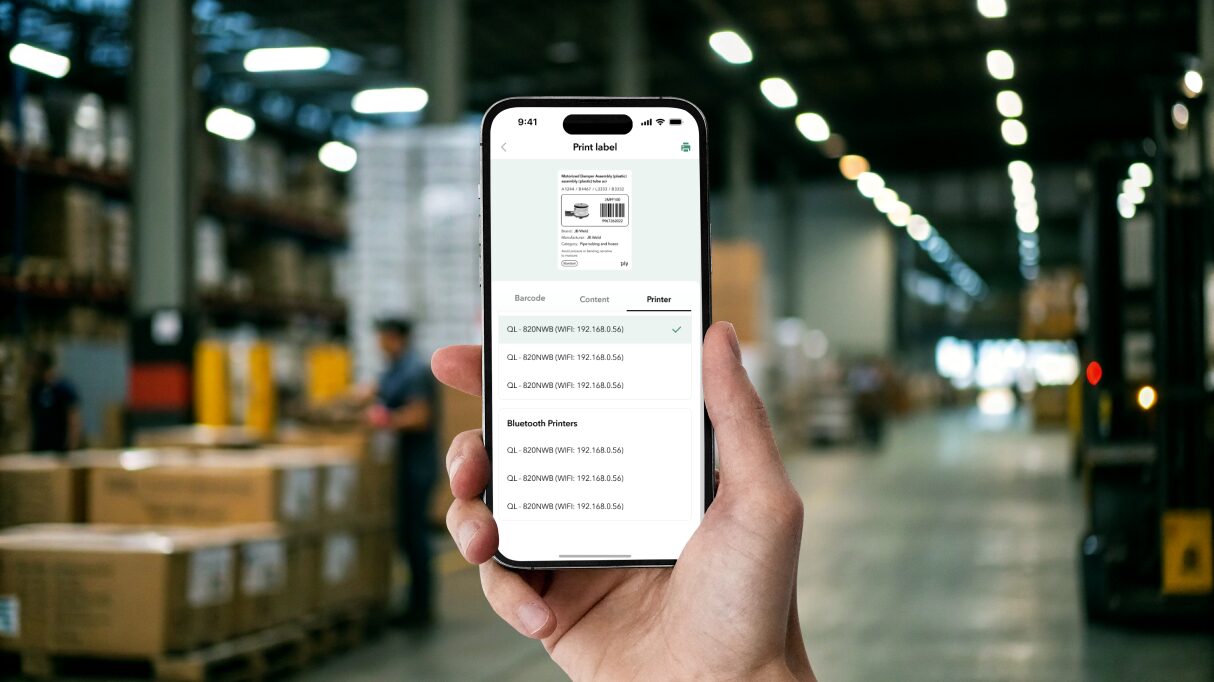

Barcodes can be scanned using a dedicated scanner or even a phone camera if you’re using an app that supports it. Either way, they’re a quick win to boost efficiency.

You can even consider a label printer to keep up with demand, avoid smudged handwriting, and worn-out stickers. We recommend picking one that’s compact, durable, and integrates easily with your inventory software of choice.

Go Deeper with NFC Tags

Near Field Communication (NFC) tags take labeling to the next level. These small, scannable tags work when tapped with a phone, unlocking more detailed info than a typical barcode.

Where to Use

- Attach to high-value tools to track location or warranty details.

- Tag equipment with service history or inspection checklists.

- Place on truck stock bins for fast reorder or usage logging.

NFC tags are a great fit for teams already comfortable with mobile tools and looking to streamline complex workflows.

Labeling Best Practices for the Field

Whether you’re labeling pipe fittings or power tools, consistency is key. Here’s what the pros recommend:

- Use heat-shrink labels for wires or cables. They stay put and hold up to heat and moisture.

- Choose durable materials like laminated or waterproof labels for outdoor or high-use items.

- Factor in climate and conditions. Humidity, heat, and dust can cause standard paper labels to peel, fade, or fall off. Go for weather-resistant adhesives and materials.

- Stick to clear, standardized naming, so everyone on the team knows what’s what.

- Place labels where they’re easy to see, even in low light or tight spaces.

And most of all, don’t forget to train your team. A label system only works if everyone knows how to use it.

Why It All Matters

Labeling isn’t just about neatness. It’s about time saved, mistakes avoided, and techs getting the job done faster. Good labels help with:

- Faster part retrieval and job prep.

- Fewer inventory mistakes.

- Smoother audits and replenishment.

- Less time wasted on “where’s that part?”