How much money is hiding in your inventory? Between parts that go missing, time wasted on supply runs, and inaccurate job costing, poor material management directly impacts your bottom line. It’s a silent profit killer.

Choosing the best inventory management software is one of the smartest financial decisions you can make for your business. It’s an investment in efficiency that pays for itself by reducing waste, improving technician productivity, and giving you a true understanding of your job profitability.

So let’s explore how to calculate the return on your investment and identify the features that will have the biggest impact on your company’s financial health.

Key Takeaways

- Choose Software Built for the Trades: A generic inventory tool won’t solve your unique challenges. Look for a system designed specifically for contractors that handles truck stock, simplifies purchasing, and gives you clear visibility into job costs.

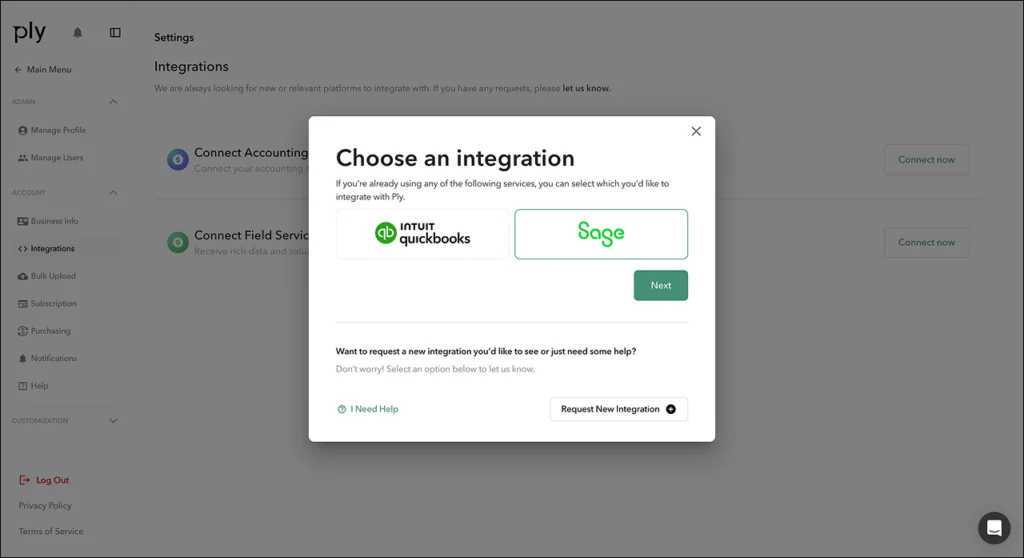

- Prioritize Seamless Integrations: Your inventory system should connect directly with your field service and accounting software. This creates a single source of truth, eliminates manual data entry, and ensures your job costing and invoicing are always accurate.

- Look Beyond Features to Future Growth: The right software should be a long-term partner. Evaluate the implementation process, training support, and the platform’s ability to scale with your business as you add more trucks and technicians.

What Makes Inventory Management Software Great?

The right inventory management software isn’t a one-size-fits-all solution. It’s the one that fits your business like a glove, streamlining your unique workflow instead of forcing you into a new one. Great software helps you manage materials, simplify purchasing, and connect the dots between your warehouse, your trucks, and your accounting books.

So, what separates the good from the great? It comes down to a few core pillars.

- First, it needs the right set of tools designed for your specific industry.

- Second, it has to play nice with the other software you already rely on every day.

- Third, it must be accessible wherever your team is working, whether that’s in the office or on a job site.

- Finally, it should automate the tedious tasks that eat up your time.

Let’s break down what to look for in each of these areas.

Key Features Every Business Needs

The best inventory software is built with your industry in mind. While basic stock counting is standard, you need features that solve your specific challenges. For trade businesses, this means going beyond the warehouse. Look for tools that let you manage truck stock, create and track purchase orders, and handle multi-location inventory with ease.

Connect With Your Other Tools

Your inventory system shouldn’t be an island. Think about your entire workflow. Your inventory software should connect directly with your field service management platform and your accounting software. These integrations create a single source of truth, ensuring that job costing, invoicing, and inventory counts are always in sync across your entire operation.

Get Real-Time Updates and Mobile Access

Your work doesn’t stop at the office door. For contractors and field technicians, mobile access is non-negotiable. A great platform will have a user-friendly mobile app that allows your team to check stock levels, look up parts, and update inventory from their phone or tablet right at the job site.

Real-time updates are just as critical. Everyone on your team should be working with the most current information, eliminating the guesswork of whether a part is actually on the truck or back at the warehouse.

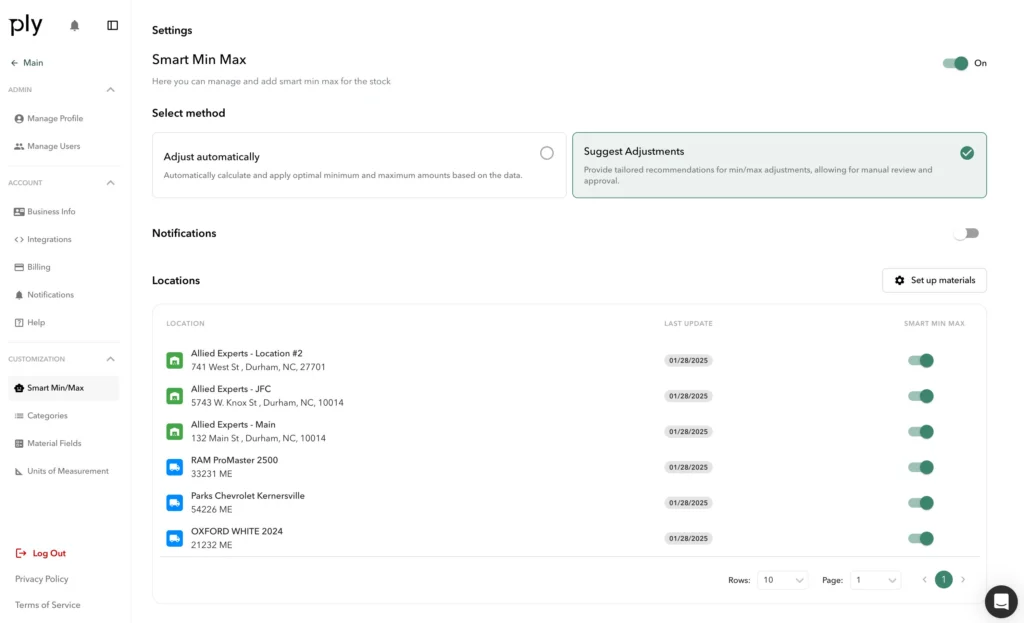

Set Up Automated Alerts and Notifications

Tired of running out of critical parts at the worst possible moment? This is where automation comes in. Top-tier inventory software lets you set up custom alerts for low stock levels, so you know it’s time to reorder long before you run out. This simple feature saves you time, reduces manual oversight, and helps you maintain the right amount of stock without tying up too much cash in excess inventory.

Comparing the Top Inventory Management Solutions

With so many options on the market, finding the right fit can feel overwhelming. Each platform is built with a specific type of business in mind, so let’s break down some of the top contenders to see how they stack up and who they’re built for.

Ply

Ply is designed from the ground up for contractors in the trades. If you run a plumbing, HVAC, electrical, or similar service business, this is your purpose-built solution. Its main goal is to simplify the entire material buying and management process, from purchasing and receiving to tracking truck stock and job costing.

The real power of Ply comes from its deep integrations with field service software like ServiceTitan, Housecall Pro, and Jobber. This connection allows for a seamless flow of information, ensuring the parts used on a job are accurately tracked against inventory and billed correctly, which helps you protect your profit margins and book more jobs.

Zoho Inventory

Zoho Inventory is a solid, general-purpose tool that’s part of the larger Zoho ecosystem of business apps. It’s a great fit for small to medium-sized businesses, particularly those in retail or e-commerce that need to manage stock across multiple sales channels. With features like real-time tracking and automation, it helps businesses keep a close eye on stock levels.

While it’s flexible and can connect to other apps, it lacks the specialized workflows for job costing, truck stock management, and direct integration with field service platforms that trade businesses depend on. It’s more of a universal tool than a specialist one.

Cin7

Cin7 is a powerful platform built for businesses that sell products across many channels. Think retailers, wholesalers, and e-commerce brands that need to sync inventory between their online store, physical locations, and marketplaces like Amazon. It excels at connecting all your sales channels, warehouses, and shipping operations into one central system. This prevents stockouts and ensures order accuracy.

However, for a trade contractor, many of its core features, like point-of-sale (POS) integration and 3PL connections, aren’t relevant to the daily workflow of managing parts for service jobs.

Katana

If you manufacture your own products, Katana is likely on your radar. It’s designed specifically for makers and small to medium-sized manufacturers. Katana shines when it comes to managing raw materials, production planning, and tracking finished goods. It gives you a clear view of your entire production process, from ordering raw materials to shipping the final product.

This focus on manufacturing makes it an excellent choice for creators, but it’s not designed to handle the unique challenges of service-based contractors who are buying and installing parts rather than producing them.

Sortly

Sortly’s tagline is “Inventory Simplified,” and it lives up to that promise. It’s an incredibly user-friendly and visual platform, making it perfect for businesses that need a straightforward way to track what they have and where it is. Its mobile app is highly rated and even works offline, which is a huge plus. You can easily create QR code labels and track items visually.

While Sortly is fantastic for basic asset and inventory tracking, it doesn’t offer the purchasing, job costing, or deep accounting integrations that a growing trade business needs to manage materials profitably.

QuickBooks Enterprise

Many businesses already use QuickBooks for their accounting, so using QuickBooks Enterprise for inventory can seem like a convenient choice. It offers robust inventory features, including advanced pricing rules, barcode scanning, and multi-location tracking, all within the familiar QuickBooks interface. It’s a strong option for distributors or retailers who want to keep their financials and inventory in one system.

The challenge for contractors is that it’s an accounting-first platform. It isn’t built to manage the dynamic needs of truck stock or seamlessly connect material usage on a job back to a work order in your field service software.

The Best Software for Your Industry

The right inventory management software isn’t one-size-fits-all. A large-scale manufacturer has completely different needs than a plumbing contractor. The best solution for your business is one that’s built with your specific industry challenges in mind, helping you save money, reduce waste, and operate more efficiently.

For Trade and Construction Businesses

For contractors in the trades, your software needs to track parts and materials across multiple vehicles and job sites to ensure your technicians have what they need to get the job done right the first time. This is where specialized solutions truly shine. While general job management software systems are great for scheduling and client communication, they often lack deep inventory features.

That’s why many businesses in the trades and construction industries pair their field service software with a dedicated inventory platform. This combination allows you to manage purchasing, track truck stock, and connect material usage directly to jobs, giving you a clear view of your profitability and operational efficiency.

For Manufacturing Operations

Manufacturing businesses juggle raw materials, work-in-progress, and finished goods. Your software must be able to handle this complexity with features like bill of materials (BOM), production planning, and full product traceability. You need to track every component from the moment it arrives at your facility to the moment the final product is shipped to a customer.

As you grow, you can move to more advanced, tiered systems that provide the detailed production and inventory controls necessary for scaling your operations.

For Small Businesses vs. Enterprises

As your business grows, your inventory needs will change. A small business might just need a simple way to track stock and avoid manual counts, while a large enterprise needs advanced analytics, multi-warehouse support, and custom workflows. The software market reflects this, with pricing and features that scale accordingly. Solutions for small businesses can start around $50 per month, offering core features to get you organized.

Enterprise-level systems can cost over $1,000 per month, providing the robust infrastructure needed to manage complex supply chains. When choosing a solution, find a platform that not only solves your current challenges but also offers a clear path to grow with your business, so you aren’t forced to switch systems down the road.

How to Choose the Right Solution

Picking the right inventory management software can feel like a huge decision. This tool will become a central part of your daily operations, so you want to get it right the first time. Instead of getting distracted by flashy features, focus on what will actually solve your biggest headaches and support your team in the field. After all, this is kind of a long-term partnership.

So what should you take into account?

First, Define Your Business Needs

Before you even look at a demo, take some time to learn exactly what you need the software to do. Are you constantly losing track of parts on service trucks? Is your purchasing process a mess of phone calls and random receipts? Or maybe you’re struggling to get accurate job costing because you don’t know what materials were actually used.

Make a simple list of your must-have features versus your nice-to-haves. This will be your guide when evaluating different options, so be specific. Instead of just “better tracking,” write down “real-time visibility into the stock on each technician’s truck.” Knowing your key performance indicators (KPIs), like inventory turnover or carrying costs, can also help you find a tool that directly addresses your financial goals.

Check for Key Integrations

Your inventory software doesn’t operate in a vacuum. To avoid creating more work for your team, it needs to connect seamlessly with the tools you already use every day. If your team lives in a field service management platform like ServiceTitan or Jobber, your inventory system should integrate directly with it. This ensures that when a technician uses a part on a job, the inventory count is updated automatically, without any manual data entry.

The same goes for your accounting software. A solid QuickBooks integration means your financial records are always accurate and up-to-date, saving your office staff hours of reconciliation.

Make a list of your essential software and put integrations at the top of your checklist. A system that doesn’t communicate with your other tools will only create data silos and frustration.

Plan for Implementation and Training

The best software in the world is useless if your team doesn’t know how to use it. When you’re talking to vendors, ask detailed questions about their implementation and training process. How will they help you get your existing inventory data into the new system? Do they offer hands-on training for your technicians and office staff, or do they just send you a link to a help article?

A smooth rollout is critical for getting your team on board. Look for a partner who will guide you through the setup and offer ongoing support. For example, Ply offers onsite warehouse implementation to help you organize your stockroom and label everything correctly from day one.

Can It Grow With Your Business?

The solution you choose today should be able to support your business for years to come. Think about your goals. Do you plan on adding more trucks to your fleet? Expanding into a new service area? Hiring more technicians? Your inventory management software needs to be scalable enough to handle that growth without breaking a sweat.

Ask about limitations on the number of users, locations, or inventory items. Choosing a flexible platform ensures that as your operations become more complex, your software can adapt right along with you.

Breaking Down the Price Tag

Figuring out the cost of inventory management software can feel like trying to read a price list in another language. With different models, tiers, and potential add-ons, it’s easy to get overwhelmed.

Let’s break down the typical pricing structures so you can understand exactly what you’re paying for and find a solution that fits your budget without any surprises.

How Subscription Models Work

Most modern inventory management software operates on a subscription basis. Instead of a massive, one-time purchase, you pay a recurring fee, usually monthly or annually. This approach is great for managing cash flow because it turns a large capital expense into a predictable operating cost. You get continuous access to the software, including regular updates and support, without having to shell out thousands of dollars upfront.

Per-User vs. Flat-Rate: What’s the Difference?

As you compare options, you’ll likely see two main pricing structures: per-user or flat-rate. Per-user pricing means your monthly cost is based on how many team members need access to the software. This can be cost-effective for smaller teams, but can get pricey as you grow.

Flat-rate pricing offers a set price for a certain number of users or features, which can be easier to budget for. Costs can range from under a hundred dollars a month for basic plans to over a thousand for enterprise-level systems, depending on the features and automation you need.

Watch Out for Hidden Costs

The monthly subscription fee isn’t always the full story. Be on the lookout for potential hidden costs that can inflate your bill. These can include one-time setup fees, charges for data migration, or extra costs for training your team.

Another big one is paying for integrations. If your inventory tool doesn’t connect easily with your accounting or field service software, you might have to pay for custom development or clunky workarounds. A platform with seamless integrations built-in is a huge advantage, saving you both money and frustration.

How to Calculate Your ROI

Ultimately, the price of the software is less important than the value it brings to your business. Before you commit, think about the return on investment (ROI). How much time will you save on purchasing? How much money will you save by reducing material waste or last-minute supply runs?

To get a clear picture, you can calculate your potential return by weighing the software’s cost against the savings in time, labor, and materials. This simple calculation will show you how the right system can pay for itself many times over.

Getting the Most From Your Software

Choosing the right inventory management software is a huge step, but the real magic happens once you start using it. Think of it like getting a new truck for your fleet: it has a ton of potential, but you won’t get far without a good driver and a maintenance plan.

To truly streamline your operations and see a return on your investment, you need to build solid habits and use the software’s features to their fullest.

Follow Inventory Tracking Best Practices

Your software is only as good as the processes you build around it. A great place to start is by organizing your physical inventory. A clean, logically arranged warehouse or service truck makes everything smoother, from finding parts to performing cycle counts.

Beyond physical organization, it’s important to think ahead. Effective inventory management is proactive, not reactive. Instead of just tracking what you have today, use your software’s data to forecast future demand. This helps you anticipate which parts you’ll need for upcoming jobs or seasonal rushes, ensuring you have the right materials on hand without overstocking and tying up cash.

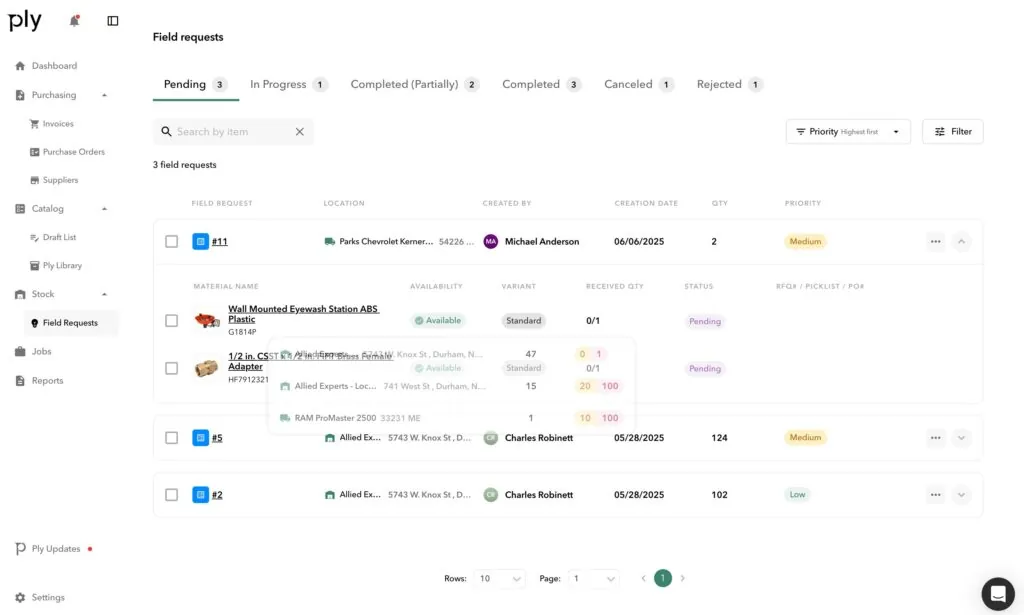

Tips for Managing Multiple Locations

For most trade businesses, “inventory” isn’t just in one place. Managing these moving targets is one of the biggest challenges, and it’s where your software can really shine. The key is to find a system that gives you a single, real-time view of all your stock, no matter where it is. This visibility is crucial for preventing a tech from driving to a job site only to realize the part they need is in another truck across town.

When every service vehicle is treated as its own mini-warehouse, you can track parts as they’re used and restock them efficiently. Good software allows you to manage truck stock management with precision, setting minimum and maximum levels for each item on each vehicle. This ensures your techs are always prepared for the day, which means fewer last-minute trips to the supply house and more completed jobs.

Set Up Your Automated Systems

One of the biggest perks of modern inventory software is automation. It’s time to let the system handle the tedious tasks so you and your team can focus on more important work. Start by setting up automated alerts for low stock levels. When a part in your warehouse or on a truck drops below a certain threshold, the system can automatically notify your purchasing manager. This simple step can virtually eliminate stockouts and the costly delays they cause.

Take it a step further by automating your purchasing process. Many platforms can automatically generate purchase orders when stock runs low and send them to your preferred suppliers for approval. This not only saves a ton of administrative time but also helps maintain consistent stock levels without any manual effort. Exploring your software’s automation features is one of the fastest ways to see a direct impact on your daily operations.

How to Monitor Performance

Once your system is up and running, you need a way to know if it’s actually working. This is where monitoring your performance comes in. Start by identifying a few KPIs that matter most to your business. These could include inventory turnover rate, the carrying cost of your stock, or how often you experience stockouts. Tracking these metrics will give you clear, data-backed insights into what’s working and where there’s room for improvement.

Regularly review reports and dashboards within your software to keep a pulse on your operations. Are certain parts sitting on the shelf for too long? Are you making too many emergency runs to suppliers? Answering these questions helps you fine-tune your strategy. You can even use an ROI calculator to see exactly how much money the software is saving you in terms of reduced waste, improved efficiency, and increased job capacity.

Overcoming Common Implementation Hurdles

Switching to a new system can feel like a big step, but it’s manageable with the right approach. Start by mapping out integrations with the other tools you rely on, like ServiceTitan or QuickBooks, so data flows smoothly.

Clean up your existing inventory data before migrating it, correcting errors and removing duplicates, then test with a small sample import to catch issues early. For training, focus on showing your team the “why” behind the change and give them hands-on practice with the tools they’ll use most. A quick troubleshooting guide and clear support contacts will help smooth out bumps as everyone adjusts.

By laying this groundwork early, you’ll turn your software from a simple tracking tool into the backbone of a more efficient and profitable business.

Advanced Features to Consider

Once you’ve confirmed a software solution has all the essential features, it’s time to look at the advanced tools that can really streamline your operations. These are the features that separate a basic digital parts list from a true inventory management system.

Think of it this way: the basics get you organized, but the advanced features are what help you grow your business smarter. When you’re comparing different platforms, pay close attention to these powerful tools. They might seem like nice-to-haves at first, but they quickly become indispensable for any trade business serious about getting its material management under control.

Predict Future Needs with Analytics

Without a clear view of what’s coming, your system is always reactive instead of proactive. The best software uses your historical data, be it parts usage, job frequency, or seasonality, to forecast future demand. This means you can anticipate needing more AC contactors before the first heatwave hits or stock up on specific furnace components ahead of winter.

This kind of forecasting helps you avoid costly emergency supply runs and ensures your techs have the parts they need to finish jobs on the first visit. It’s a critical tool for managing cash flow and can have a huge impact on your profitability.

Create Custom Reports

Standard reports are useful, but the ability to create custom reports gives you the power to dig deeper into your own data. You can build reports to see the total inventory value on each truck, track which parts are used most frequently by specific technicians, or analyze material costs per job type. This level of detail is essential for accurate job costing, strategic planning, and identifying opportunities to save money.

What to Look for in Security

Your inventory data contains sensitive business information, including supplier pricing, job costs, and even customer details. That’s why security is non-negotiable. Look for software that follows important security and privacy rules. For example, platforms like Ply are SOC 2 compliant, which means an independent third party has verified that the company has strong systems in place to protect your data.

Also, check for features like role-based user permissions, which let you control who can see and change what. This ensures your technicians can manage their truck stock without having access to the company’s financial data.

Manage Inventory From Anywhere with Mobile Access

For any trade business, work happens in the field, not behind a desk. Your inventory management software needs to keep up. A powerful and easy-to-use mobile app is essential for your technicians. It allows them to check parts availability, update stock levels, and find materials right from a job site.

Top-tier apps, such as Ply, even let techs use their phone’s camera for barcode scanning and work offline, syncing the data once they’re back online. This real-time access means fewer trips back to the warehouse and less time wasted, allowing your team to complete more jobs each day.

Frequently Asked Questions

Why is it so important for my inventory software to connect with my field service platform? Think of it as creating a single, seamless workflow. When your inventory system integrates directly with a platform like ServiceTitan or Jobber, the parts a technician uses on a job are automatically deducted from stock and added to the invoice. This connection eliminates manual data entry, prevents billing errors, and gives you a real-time, accurate picture of your job costs and profitability without any extra effort.

My biggest problem is managing parts on my trucks. What should I look for? You need a system that treats each truck as its own mobile warehouse. Look for software with a strong mobile app that allows technicians to see exactly what they have on their vehicle and what’s available on other trucks or back at the shop. The best solutions let you set minimum stock levels for each truck, making it easy to see what needs to be restocked before the day even begins.

I’m currently using spreadsheets to track inventory. When is it time to switch to dedicated software? Spreadsheets are a great starting point, but you’ll know it’s time to switch when you start spending more time updating them than they’re worth. If you’re struggling with inaccurate counts, running out of critical parts unexpectedly, or can’t get a clear view of your job costs, that’s your sign. Dedicated software automates these tasks and gives you the real-time visibility you need to run your business more efficiently.

My technicians aren’t tech-savvy. How can I get them to actually use new software? The key is choosing software that is genuinely easy to use and demonstrating how it makes their job easier. A simple, intuitive mobile app is non-negotiable. During training, focus on the benefits for them, like no more last-minute trips to the supply house or frantic calls to the office to find a part. When they see the tool as a way to finish jobs faster, adoption becomes much smoother.

Is it better to pay per user or a flat rate for my growing team? There’s no single right answer, but it comes down to your growth plans. A per-user model can be more affordable when you’re small, but the costs can add up quickly as you hire more people. A flat-rate plan provides more predictable costs, which can be easier to budget for as you expand. Consider where your business will be in a year or two and choose the model that offers the most flexibility for that future.