Let’s face it; when jobs are stacking up and materials are running low, it’s tempting to just text your supplier or call in a quick order. But without a solid purchase order (PO) process, things get messy. Fast.

Miscommunication. Over-ordering. Missing materials. And worst of all? You lose visibility into your spend. That’s where a smart PO system makes all the difference.

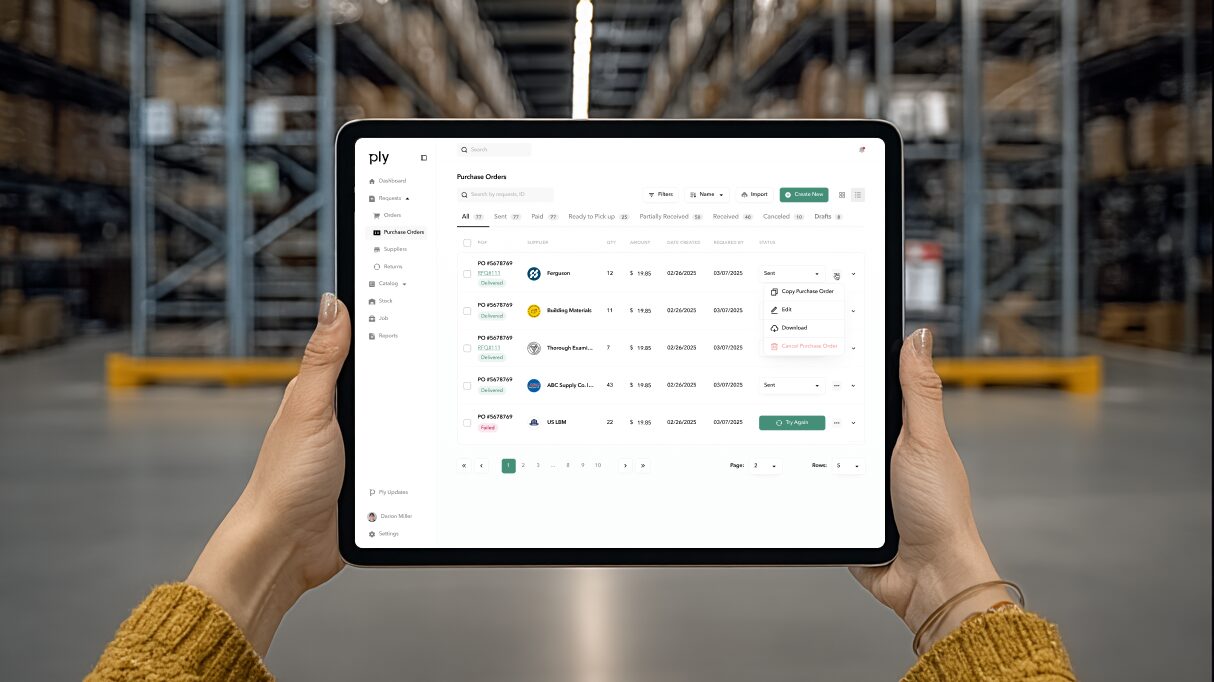

Whether you’re running a warehouse, managing a few trucks, or juggling vendors across projects, POs (and RFQs) are the backbone of a smoother, more efficient inventory operation. Let’s break it down.

What’s a Purchase Order (and Why Should You Care)?

A PO is a formal record of what you’re buying, who you’re buying it from, and when you expect it. It sounds simple, but it solves a ton of headaches:

- You know what’s coming in and when.

- You can track costs down to the job or department.

- You reduce double-ordering and material waste.

Without POs, you’re relying on memory and handshakes. With them, you’re running a business with traceable, accountable systems.

The Real Cost of Poor PO and Procurement Management

It’s not just about paperwork. Reports show that average supply chain costs hit about 13.2% of revenue, with the best companies reducing this to around 7.9%, which equals a potential 40% savings.

Without a clear PO process, materials fall through the cracks. Orders are duplicated, deliveries go unchecked, and returns become nearly impossible to track. And while the paperwork might seem minor, the ripple effects hit hard, causing delays, cost overruns, and frustrated teams.

Just ask Kyle Plumbing. While logging materials into Ply, their team uncovered $60,000 worth of unused stock sitting on shelves. By tracking down the original POs, they were able to return everything and recover the cost. From there, they put a tighter PO process in place to make sure nothing slipped through the cracks again.

PO vs. RFQ: What’s the Difference?

We know; it’s hard to keep up with all the letters and abbreviations, but it’s important to understand which is which. Here’s how they stack up:

- POs (Purchase Orders): Used when you already know who you’re buying from. Maybe it’s your go-to vendor, or maybe you’ve priced it out already. This is the official green light.

- RFQs (Request for Quotes): Used when you’re still shopping. RFQs let you request pricing and availability from multiple suppliers before placing the final order.

Using RFQs helps you make smarter purchasing decisions. Using POs helps you keep a clean paper trail. Together, they make your procurement process more strategic and less reactive.

Building a Smarter PO Workflow

Your purchase order process should do more than just place orders. It should keep your team aligned, reduce errors, and give you full visibility from quote to receipt. So what does a strong PO workflow look like in practice? Here’s some tips:

- Clear approvals: Set rules around who can create and approve POs. This prevents duplicate orders and ensures accountability.

- Delivery expectations: Specify when and where materials should arrive, whether it’s a warehouse, a jobsite, or a tech’s truck. It helps avoid delays and “I thought that already came in” confusion.

- Job or truck tracking: Tie every PO to a specific project, location, or technician so you can follow the materials all the way to their final destination.

- Consistent material naming: Make sure your internal SKUs, material IDs, and descriptions match what suppliers are calling those items. Misalignment between them is one of the biggest causes of wrong deliveries and order confusion, especially if your team uses nicknames or abbreviations.

- Receipts and reconciliation: Check off what arrives (and what doesn’t) as it’s delivered. This keeps inventory accurate and makes it easier to return overages or incorrect items.

Closing

Your PO system doesn’t have to be complicated; it just has to be consistent. Even small changes can make a big impact. Start with one piece of the puzzle: maybe it’s rolling out RFQs to compare vendor pricing, or setting up a receipt process so you know exactly what came in.

From there, you can layer in approvals, delivery tracking, and real-time updates to take full control of your purchasing process.

Because when your orders are organized, your spend gets smarter, your techs waste less time chasing parts, and your jobs move forward without surprises. In short, a solid PO process doesn’t just manage materials, it powers your entire operation.