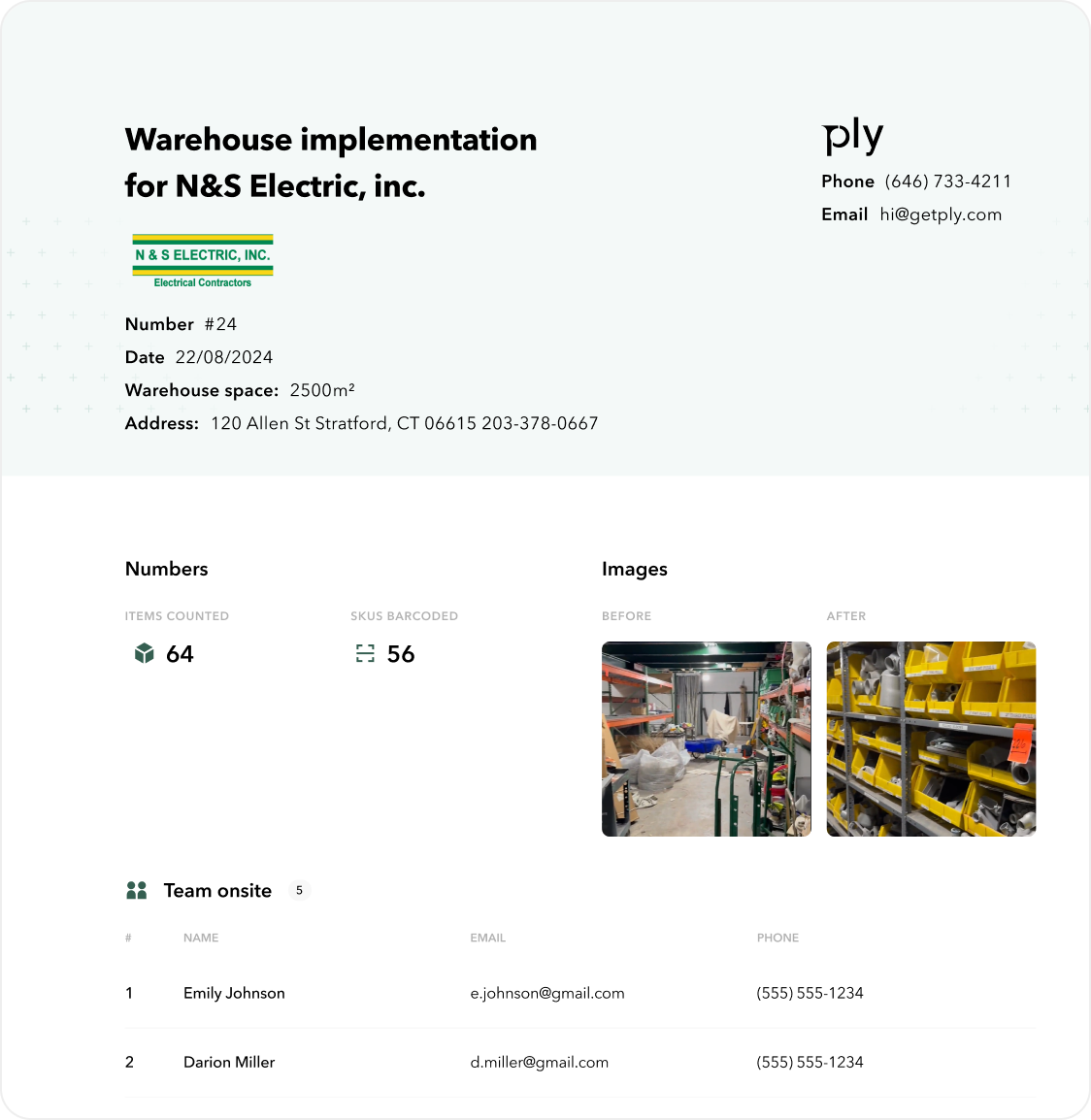

Overwhelmed by stock management or struggling to track items in real-time? Our onsite implementation streamlines your warehouse, helping you sort, count, and organize inventory while introducing tools like barcoding for seamless management.

Train your team to use Ply to its fullest potential. This includes learning how to barcode, intake, and manage materials and their quantities, as well as creating warehouses and trucks.

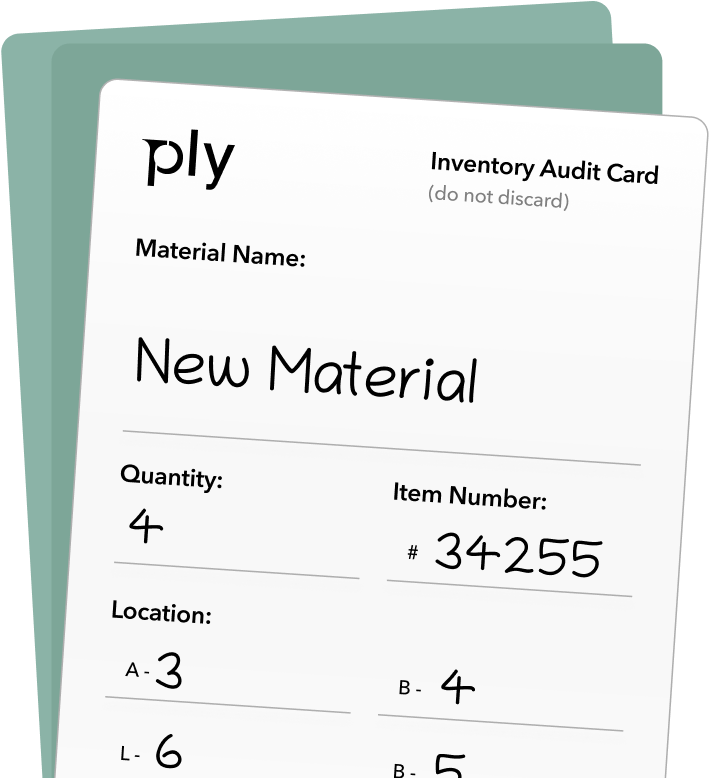

Counting, sorting, barcoding and working on catalog intake.

Training your team to use Ply to its fullest potential. This includes learning how to barcode, intake, and manage materials and their quantities, as well as creating warehouses and trucks

Jump-starting your warehouse implementation so your team is able to finish the job after our in-person time.

Cleaning tasks, such as power washing.

Inventorying every single item. We'll focus on the most impactful areas that will provide valuable insights for improvement.

Before creating a customized warehouse implementation proposal, we’ll start with an initial virtual walk-through. During this session, we’ll explore your space, identify key sections, calculate SKUs, assess your current organization system, and pinpoint opportunities for greater efficiency.

Mark items you would like to omit from the counting.

Throw out all trash and unwanted items in the trucks.

Label items according to what your team calls them.

Sort and organize bins and items where you’d like them to remain.

Ensure participants are available for training.

Assign a point person and team members for real-time learning.

Get Started Today

Got 30 minutes?

Drop us a line and we'll schedule a call to demonstrate all the benefits of Ply.

Get Started Today

Drop us a line and we’ll schedule a call to demonstrate all the benefits of Ply.

Dave Wigder

Co-founder of Ply